Table of Contents

As global atmospheric CO2 concentrations hover near 425 ppm, the built environment faces a structural reckoning: the traditional reliance on high-heat industrial processing for infrastructure is no longer compatible with planetary boundaries. The debate of Mass Timber vs. Steel is not merely a choice of aesthetics; it is a critical pivot in how we quantify the energetic debt of our cities. While steel has defined the verticality of the last 150 years, the shift toward regenerative infrastructure requires materials that function as carbon sinks rather than carbon sources.

The Nuvira Perspective: Engineering a Carbon-Negative Skyline

At Nuvira Space, we view the building envelope as a sophisticated biological and mechanical interface. We do not design for static completion; we design for 100-year performance cycles. Our authority is rooted in the belief that luxury and institutional stability must be decoupled from extraction. By prioritizing mass timber over conventional steel-and-concrete skeletons, we aren’t just selecting a renewable resource—we are implementing a high-precision, prefabricated structural system that yields superior thermal performance, faster capital rotation, and a visceral biophilic connection that increases human productivity by 15% in commercial environments.

Our methodology aligns with the architectural shift toward holistic decarbonization, mirroring the institutional rigor found in the American Institute of Architects (AIA) Framework for Design Excellence. By adopting these standards, you are not merely building; you are participating in a global movement toward environmental accountability and long-term asset resilience.

Technical Deep Dive: Mass Timber vs. Steel – 7 Vital Lifecycle Cost Insights

To navigate the transition from extractive to regenerative infrastructure, you must analyze the material performance through a rigorous Life Cycle Assessment (LCA). Here is the data-driven reality of how these metrics dictate the functionality of your next urban tower.

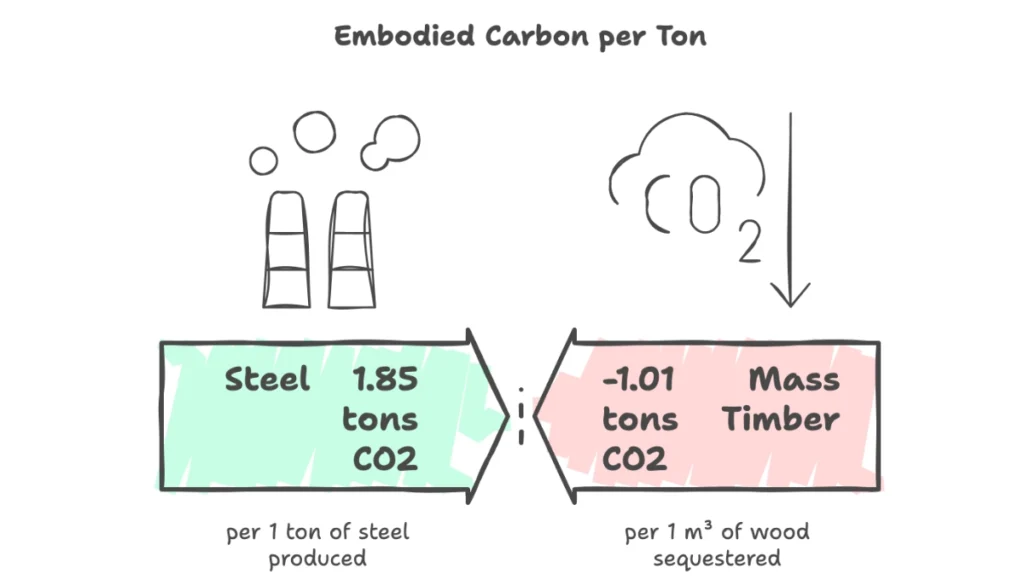

1. Mass Timber vs. Steel: Embodied Carbon Debt vs. Sequestration Credits

Steel production remains one of the most carbon-intensive industrial processes on the planet. Blast furnaces operating at 1,500°C emit approximately 1.85 tons of CO2 for every 1 ton of steel produced. This is “upstream” carbon that can never be recovered. In contrast, mass timber (specifically Cross-Laminated Timber, or CLT, and Glued Laminated Timber, or Glulam) functions as a carbon vault.

- Mass Timber Sequestration: Biogenic carbon storage allows mass timber to sequester approximately 1,010 kg of CO2 per 1 m³ of wood. This creates a “negative” carbon footprint at the point of installation.

- Steel Footprint: A typical 20-meter span beam assembly generates an embodied carbon footprint of 12,000 kg to 15,000 kg.

- AIA Alignment: In recent AIA sustainability reports, the emphasis has shifted from operational energy to embodied carbon. Data indicates that embodied carbon will account for nearly 50% of total new construction emissions between now and 2050.

- The “So What?”: Choosing timber allows you to reach “Net Zero” thresholds without relying on expensive, unverified carbon offsets. You are effectively “printing” carbon credits directly into your structural frame.

2. Thermal Performance: Mass Timber vs. Steel Energy Flux

The thermal conductivity of steel is 50 W/m·K, making it a massive thermal bridge. In a steel-framed building, the structural members actively facilitate the transfer of heat out of the building in winter and into the building in summer. CLT has a conductivity of 0.13 W/m·K—nearly 400 times more resistant to heat flow.

- Operational Savings: Timber’s airtightness and natural insulation reduce HVAC demand by 25% to 40% annually. This translates to smaller mechanical plants and more leasable square footage.

- U-Value Impact: A 100 mm CLT panel provides an inherent U-value of 1.1 W/m²K. When integrated with Nuvira’s high-performance envelope, we achieve system-wide R-values that exceed ASHRAE 90.1 standards by 30%. This level of precision is achieved through a controlled modular vs. prefab approach, ensuring that every thermal joint is optimized before arriving on-site.

- The Lived Experience: Occupants in timber-heavy environments report fewer “cold spots” and a more stable mean radiant temperature. Beyond thermal stability, these spaces are frequently enhanced by biophilic interior design, which together create a restorative atmosphere that reduces utility overhead while improving cognitive function.

3. The Velocity of Assembly and Capital Rotation

In the commercial real estate world, time is the ultimate variable in the Internal Rate of Return (IRR) equation. Mass timber is 20% to 30% lighter than steel and 80% lighter than concrete. This allows for smaller foundation piles and significantly faster vertical growth through prefabrication.

- Speed Metric: A timber floor plate can be installed in 2.5 hours compared to 2 days for a steel-decking and concrete-pour sequence.

- Construction Window: On average, mass timber structures are completed 25% faster than their steel counterparts.

- The “So What?”: For a 20-story tower, this translates to 4 months of early occupancy. If your monthly rent roll is $500,000, you have just captured $2,000,000 in early revenue while simultaneously reducing your construction loan interest carry.

4. Acoustic Performance and Mass Density

The industrial aesthetic of steel often comes with an “acoustic debt.” Steel requires multi-layered gypsum, resilient channels, and acoustic batts to achieve a Sound Transmission Class (STC) of 50. A 5-layer CLT panel (175 mm) provides a natural, high-density barrier.

- Decibel Reduction: Timber structures naturally dampen high-frequency sounds, creating 35 dB to 45 dB of internal isolation.

- Vibration Control: Because wood has a higher damping ratio than steel, it absorbs footfall noise and mechanical vibrations more effectively.

- The “So What?”: In high-end residential or laboratory environments, this natural acoustic “softness” eliminates the need for expensive secondary floor treatments, reducing your interior fit-out costs by $5 to $12 per square foot.

5. Fire Resistance and Char Dynamics: The Myth of Vulnerability

The most persistent barrier to mass timber adoption is the misconception regarding fire safety. However, massive wood behaves more predictably than steel in extreme heat. Steel loses 50% of its structural integrity at 550°C, leading to sudden, catastrophic collapse as the material “wilts.”

- Char Rate: CLT chars at a consistent, predictable rate of 0.65 mm per minute. This char layer acts as a natural insulator, protecting the structural core of the wood from heat penetration.

- Safety Margin: A 90-minute or 120-minute fire rating is achieved through “sacrificial” timber layers.

- Institutional Data: AIA-endorsed case studies of tall timber buildings, such as the Mjøstårnet in Norway, demonstrate that these structures remain standing even after total burnout of contents, whereas steel structures often require total demolition post-fire due to tempering of the metal.

6. Foundation Load Mitigation and Site Versatility

The reduced self-weight of timber (approximately 500 kg/m³) versus steel/concrete (2,500 kg/m³) changes the geography of development. You can now build on “soft” urban sites, near subway tunnels, or on top of existing parking garages where a steel building would be too heavy.

- Substructure Savings: You can expect a 10% to 15% reduction in total foundation costs. In seismic zones, the lower mass of timber reduces lateral forces (F=ma), allowing for lighter and cheaper shear walls.

- Urban Infill: This lightweight profile allows for “vertical extensions”—adding 3 to 5 floors on top of an existing masonry building where steel would have required expensive structural reinforcement of the entire column line.

7. End-of-Life Circularity and Deconstruction Credits

Traditional steel recycling is a carbon-intensive “downcycling” process. Mass timber elements are designed for “Design for Disassembly” (DfD).

- Repurposing Rate: 90% of timber beams can be salvaged, re-graded, and reused in new structures.

- Carbon Perpetuity: Because the carbon remains sequestered in the wood even after the building is dismantled, the material remains a net-positive asset on the balance sheet of the next generation.

Comparative Analysis: Nuvira Regenerative Standard vs. Industry Baseline

| Performance Metric | Steel Industry Standard | Nuvira Mass Timber Solution |

|---|---|---|

| Embodied Carbon | +1.85t CO2 / ton | -1.01t CO2 / m³ (Sequestered) |

| On-site Labor | 40-60 Workers (High risk) | 10-15 Workers (Low risk/Quiet) |

| Waste Stream | 8% Material Loss | < 1% CNC Precision |

| Seismic Response | Heavy Lateral Loads | High Ductility / Low Mass |

| Occupant Health | Neutral / Synthetic | Biophilic / Low Cortisol |

Concept Project Spotlight: Speculative Internal Concept Study “Aura Tower” by Nuvira Space

Project Overview

- Location: Copenhagen, Denmark (Nordhavn District)

- Typology: Mixed-use Residential, Bio-Research Lab, and Public Plaza.

- Vision: A 28-story vertical forest that serves as a carbon-negative lighthouse for the Baltic region, utilizing the AIA COTE (Committee on the Environment) Top Ten criteria as a design benchmark.

Design Levers Applied

- Structural Grid: 6 meter x 9 meter Glulam column-and-beam system with a central CLT core.

- Envelope: Triple-glazed high-performance skin with 240 mm CLT backing, integrated with automated solar shading.

- Metric Impact: The Aura Tower stores 4,200 tons of CO2. By displacing the steel and concrete required for a similar building, it prevents an additional 3,500 tons of emissions.

- The “So What?”: The total carbon benefit is 7,700 tons—equivalent to taking 1,600 cars off the road for a year.

Transferable Takeaway

The Aura Tower proves that the “Green Premium” is a myth when lifecycle speed and foundation savings are factored into the initial Pro Forma. You are not paying for “better” materials; you are paying for a more efficient, industrialised construction process that delivers a premium, biophilic product to the end-user.

2030 Future Projection: The Bio-Digital Era

By 2030, we anticipate that carbon taxation in markets like the EU and North America will reach 150 EUR to 200 USD per ton. In this landscape, steel-intensive buildings will become “stranded assets”—financially unviable due to high operational costs and carbon penalties.

Nuvira Space is currently developing “Living LCAs” that use IoT sensors embedded in the CLT panels to track moisture, carbon stability, and structural health in real-time. This data will be integrated into “Digital Twins,” allowing owners to trade the sequestered carbon on voluntary markets as the building ages. Your regenerative infrastructure is no longer a depreciating asset; it is a dynamic participant in the global carbon economy.

Comprehensive Technical FAQ

Q: Does mass timber increase the insurance premiums for urban towers?

A: Currently, initial premiums may be 3% to 5% higher due to actuarial unfamiliarity. However, insurance giants are beginning to recognize the “low-volatility” nature of timber fire performance. Nuvira works with underwriters to provide full-scale burn test data, which often results in premiums equal to or lower than steel-and-concrete once the building is operational.

Q: How does timber handle the humidity of tropical cities like Singapore?

A: We utilize a “layered defense” strategy. This includes 3 mm vapor-permeable membranes, factory-applied hydrophobic coatings, and “smart” CNC-milled joinery that allows for 2 mm of natural expansion and contraction without compromising the structural seal. The timber remains “breathable” but protected.

Q: Can mass timber match the spans of steel for large-scale institutional lobbies?

A: Yes. Using Delve-free Glulam trusses and hybrid timber-steel connectors (where steel is used only for tension), we can achieve clear spans of 20 to 30 meters. For spans exceeding 40 meters, we implement a carbon-negative hybrid system using high-tension timber cables, maintaining a 90% wood-by-volume ratio.

Q: What is the impact on the supply chain? Is there enough wood?

A: Regenerative infrastructure relies on certified forests (FSC/PEFC). In North America alone, the forest growth exceeds the harvest rate by approximately 30%. Utilizing timber for construction provides a financial incentive for landowners to keep forests as forests rather than converting them to agricultural or sprawl development.

Scale the Future with Nuvira Space

The transition to carbon-negative architecture is no longer a choice—it is a competitive necessity. Whether you are a developer looking to maximize IRR or an architect aiming to leave a regenerative legacy, the data is clear: Mass timber is the superior structural medium for the 21st century.

Partner with Nuvira Space to engineer your next regenerative masterpiece.