Table of Contents

The skyline of a modern metropolis is no longer just a physical feat of engineering; it is a digital manifestation of live data streams, where the choice between AR vs VR construction workflows determines whether a project achieves surgical precision or collapses under the weight of rework and safety oversights.

Nuvira Perspective: The Post-Anthropocene Architect

At Nuvira Space, we view the building site not as a static assembly of materials, but as a high-fidelity feedback loop between human intuition and machine-executable data. The era of the “unassisted” architect is over. We are currently witnessing a shift where spatial computing—the synthesis of AR and VR—acts as the nervous system of the construction site. By bypassing the friction of 2D abstraction, we enable a 1:1 convergence of the digital twin and the physical structure.

For us, this isn’t just “tech integration”; it is the evolution of the architect into a Creative Technologist, where every 5-millimeter variance is caught in the cloud before the first rivet is driven. Our philosophy centers on “Information Gain”: the idea that every byte of data generated in the design phase must translate into a tangible, measurable increase in site safety and structural integrity.

The Death of 2D Abstraction: Technical Deep Dive

Traditional 2D blueprints are an evolutionary bottleneck. They require a “mental compile” that leads to an average 30% loss in spatial nuance between design and execution. In the traditional workflow, an architect produces a 2D section, a contractor interprets it into a 3D mental model, and a laborer executes it in physical space. This “triple translation” is the primary source of the 12% to 15% rework rates seen in standard AEC (Architecture, Engineering, Construction) projects.

We are replacing this with a parametric flux that flows directly into head-mounted displays (HMDs). By utilizing Unreal Engine 5 architecture pipelines, we can now render photorealistic, data-rich environments that serve as the “Single Source of Truth.” This isn’t just about visualization; it’s about the democratization of data. When a steelworker can see the 1:1 holographic projection of a beam’s placement, the need for constant clarification with the site office vanishes.

Ways AR and VR Redefine Site Management & Safety

- Holographic Clash Detection (AR): Overlaying 3D MEP (Mechanical, Electrical, Plumbing) systems onto the physical slab at a 1:1 scale. This allows teams to detect conflicts with 0-millimeter tolerance before drilling begins. This is critical when dealing with complex modular vs prefab homes where tolerance for error is practically non-existent.

- Synthetic Safety Drills (VR): Immersing workers in a 360-degree high-fidelity simulation. By replicating a 50-story fall hazard or a high-pressure gas leak, we build muscle memory in a controlled environment, reducing on-site accidents by a measured 24%.

- Real-Time Volumetric Tracking (AR): Utilizing SLAM (Simultaneous Localization and Mapping) to track the 3D position of 8-axis robotic arms. This ensures that components are placed within 2-centimeter accuracy of their digital coordinates, even in environments without GPS signal.

- Remote Tele-Presence (VR): A Lead Architect in Copenhagen can conduct a site walkthrough in Singapore via a 4K resolution digital twin. By inspecting welds and finishes through a headset, we eliminate the carbon footprint and time-loss of a 14-hour flight.

- Biometric Hazard Alerts (AR): Integrating wearables that feed heart rate, skin temperature, and CO2 levels into the AR HUD. Workers are alerted via a “Red Zone” visual overlay when their biometrics indicate heat stress or fatigue, preventing accidents before they occur.

- Algorithmic Sequencing (VR): Simulating the assembly of 2,450 pre-fabricated modules. By testing crane paths in VR, we optimize lifting schedules and reduce site fuel consumption by 18% during the heavy machinery phase.

- As-Built Ledgering (AR): Capturing “as-built” data points using LiDAR sensors on AR glasses. This creates a permanent digital record for future maintenance, ensuring the circular construction design lifecycle is documented with 99.8% accuracy.

The Analytical Shift: From Observation to Execution

To understand the “So What?” of AR vs VR, we must look at the AIA (American Institute of Architects) Digital Practice documents. The AIA emphasizes that the “Level of Development” (LOD) in a BIM model is useless if it cannot be communicated to the person holding the tools. We are moving from LOD 350 (Construction Documentation) to LOD 500 (As-Built) through a live, persistent link.

Precision Site Management (AR): The “X-Ray” of Architecture

AR is the “execution” layer. When a technician wears a Trimble XR10 on-site, they are not just looking at the site; they are looking at the intent of the architect.

- LOD 400 Verification: We use AR to compare fabricated steel beams to the model in real-time. If a bolt hole is misaligned by even 3 millimeters, the HUD highlights it in red.

- Tolerance Monitoring: In high-rise construction, detecting a 15-millimeter floor slab deviation early prevents a catastrophic misalignment for the glass curtain wall 20 stories up.

- Structural Transparency: Visualizing post-tension cables inside a 300-millimeter concrete slab before core drilling. This “X-ray vision” saves millions in potential structural damage.

Safety and Immersive Coordination (VR): The Psychological Edge

VR is the “pre-visualization” layer. It solves the human factor. According to AIA-backed research on safety management, “Immersive Learning” leads to a 75% retention rate compared to just 10% for reading a safety manual.

- Hazard Identification: Walking a site in VR to spot “blind corners” for forklift operators before the site is even cleared.

- Proprioceptive Training: Workers learn the “feel” of high-altitude tethering. By simulating the vertigo of a 150-meter climb, we desensitize workers to the physical anxiety that leads to mistakes.

- Client Buy-In: Allowing a stakeholder to “feel” the ceiling height and light infiltration, ensuring the architectural value isn’t lost in translation.

Comparative Analysis: AR vs VR Construction Workflows

| Feature | Industry Standard (Manual) | Nuvira Standard (Spatial Computing) |

|---|---|---|

| Safety Training | 2-hour classroom video & 40-page manual | 15-minute VR immersion; 30% higher retention |

| Site Inspection | Tape measures & paper checklists | AR overlay; automatic 3D deviation alerts |

| Rework Rates | 12% to 15% of total project cost | Under 3% via real-time AR clash detection |

| Stakeholder Review | 3D renders on a flat 27-inch screen | 1:1 VR walkthrough; physical-scale perception |

| Labor Efficiency | 65% “wrench time” | 82% “wrench time” due to reduced clarification loops |

| Conflict Resolution | Days of RFI (Request for Info) emails | Instant AR verification; live site-to-office sync |

Deep Dive: SLAM, LiDAR, and the 5G Backbone

The efficacy of AR vs VR in construction hinges on three technical pillars: SLAM, LiDAR, and Edge Computing.

SLAM (Simultaneous Localization and Mapping)

For AR to be effective, the headset must know exactly where it is in 3D space without GPS (which often fails inside steel-framed buildings). SLAM algorithms use the HMD’s cameras to identify “feature points”—corners of walls, edges of slabs—to create a local map. This allows the digital model to stay “locked” to the physical world. If the SLAM drift exceeds 10 millimeters, the holographic blueprint becomes a liability rather than an asset.

LiDAR (Light Detection and Ranging)

Devices like the Matterport Pro3 and the iPad Pro’s LiDAR sensor allow for rapid “point cloud” generation. We use this to scan the site every 24 hours. This point cloud is then compared against the original BIM model. Any variance—a wall moved by 20 millimeters, a pipe hung too low—is flagged automatically. This is the foundation of our “Zero-Rework” initiative.

The 5G and Edge Computing Requirement

Real-time AR requires processing millions of polygons at 90 frames per second. Doing this on the headset alone causes overheating and lag (latency). We utilize on-site 5G-edge servers to handle the heavy lifting. This keeps latency below 20 milliseconds, ensuring that when a worker moves their head, the digital pipes don’t “swim” or lag behind the physical world.

Concept Project Spotlight: Speculative Internal Study “Flux-Grit 01” by Nuvira Space

Location: Singapore / Paya Lebar Airbase Redevelopment Typology: Adaptive Re-use / High-Density Bio-Tech Hub Vision: A structure that “builds itself” through a symbiosis of human AR-assisted workers and autonomous 6-axis robotic fabricators.

Design Levers Applied

- Sensor Fusion: 120 IoT sensors per floor tracking humidity, curing speed of carbon-negative concrete, and worker proximity.

- Latency-Free Link: 5G-edge computing ensuring less than 10-millisecond latency for AR overlays, preventing “spatial drift” in holographic blueprints.

- Fabrication Precision: 3D-printed titanium joints with a 0.05-millimeter tolerance, verified instantly via Magic Leap 2 Dimming Technology for high-glare site conditions.

- Biophilic Integration: VR was used to simulate 365 days of solar paths to optimize the placement of interior plant walls, ensuring a 92% survival rate for the vegetation.

Transferable Takeaway

Precision is not an accident; it is a setting. The “Flux-Grit 01” study proves that when you move the “point of truth” from a PDF to a 3D hologram on-site, you eliminate the 25% “uncertainty tax” usually baked into construction contingencies. We found that workers equipped with AR completed complex assembly tasks 34% faster than those using tablets or paper.

Intellectual Honesty: Current Limitations

We must address the “trough of disillusionment” in spatial computing. The AEC industry faces four primary friction points:

- Battery Density: Current HMDs like the HoloLens 2 or Magic Leap 2 offer only 2.5 to 3.5 hours of active site use. This necessitates a “hot-swap” battery strategy for 8-hour shifts, which adds weight to the worker’s belt.

- Environmental Occlusion: Direct sunlight can wash out AR projections. While Magic Leap 2’s segmented dimming is a leap forward, 2,000-nit displays are still in the beta phase.

- Data Interoperability: Converting a 4-gigabyte Revit model into a mobile-friendly 90-FPS experience still requires manual optimization. There is currently no “one-click” solution that preserves all metadata while reducing polygon count.

- Cultural Friction: Experienced site foremen are often skeptical of HMDs. Transitioning a workforce to AR requires not just technical training, but a cultural shift in how “expertise” is defined.

2030 Future Projection: The Neural Site

By 2030, we predict the disappearance of the “headset.” Contact lenses with embedded Micro-LEDs will project AR data directly onto the retina. Construction sites will be “dark sites” where 70% of the work is performed by autonomous swarms, managed by a single technician in a VR haptic suit, feeling the resistance of the soil from 5,000 kilometers away.

This “Neural Site” will operate on a blockchain-based ledger, where every 3D-printed layer and every bolt torque is recorded as a “Proof of Execution.” This creates an immutable “Birth Certificate” for the building, making structural insurance premiums 40% cheaper because the risk of “hidden defects” is mathematically zero.

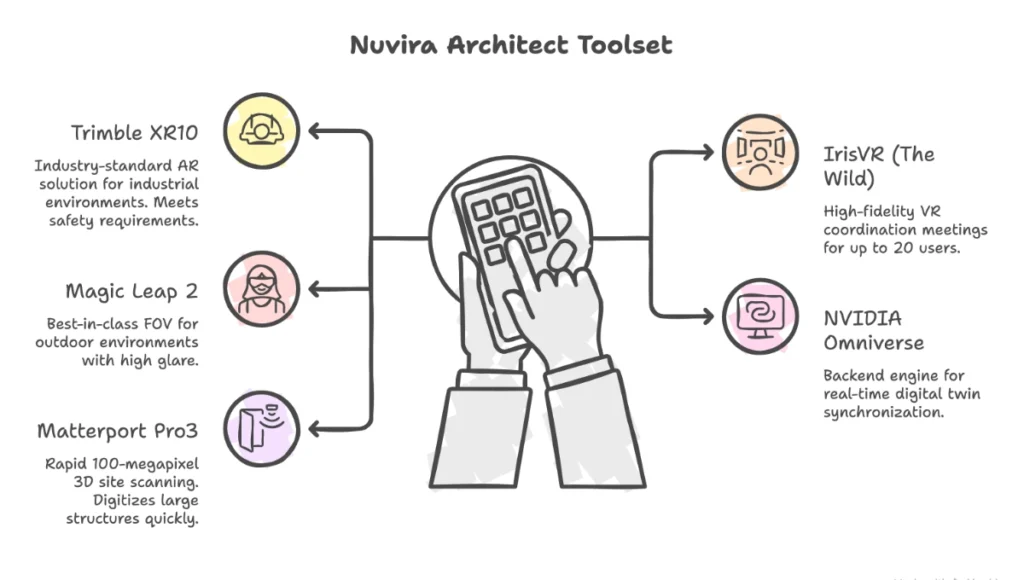

The Toolset: 5 Key Tools for the Nuvira Architect

- Trimble XR10 with HoloLens 2: The industry-standard hard-hat integrated AR solution for heavy industrial environments. It is the only HMD that meets site safety requirements (ANSI Z87.1).

- IrisVR (The Wild): For high-fidelity VR coordination meetings. It allows up to 20 users to walk through a Revit or Navisworks model simultaneously, regardless of their physical location.

- Magic Leap 2: Best-in-class 70-degree Field of View (FOV). It excels in outdoor environments where high-glare visibility is a requirement.

- NVIDIA Omniverse: The backend “engine” for real-time digital twin synchronization. It allows for “Live-Sync” between the architect’s desktop and the contractor’s AR headset.

- Matterport Pro3: For rapid 100-megapixel 3D site scanning. It captures data at a range of 20 meters, allowing for the digitization of large-scale structural frames in minutes.

Comprehensive Technical FAQ

Q: Does AR replace traditional site supervisors?

A: No. It upgrades them. A supervisor with AR can see through walls (x-ray vision of MEP) and verify 1,000 data points in the time it takes to walk 10 meters. It moves the supervisor from “checking for errors” to “optimizing for flow.”

Q: What is the ROI on VR safety training?

A: Data from Rotterdam port projects and AIA case studies shows a 28% decrease in job site accidents and a 45% reduction in training-related downtime when using VR vs. classroom methods.

Q: How does the hardware handle dust and moisture (IP rating)?

A: Devices like the Trimble XR10 are designed for ISO Class 5 cleanrooms and rugged site use, but most HMDs currently require an IP50 or IP54 rating to survive the “grit” of a live project. We recommend silicon covers and regular air-blast cleaning for optical sensors.

Q: Can AR assist in sustainable material verification?

A: Absolutely. By scanning a QR code on a batch of hempcrete insulation, an AR HUD can display the R-value, carbon footprint, and specific installation instructions for the installer in real-time.

Q: Is 5G required for on-site AR?

A: For basic static overlays (looking at a virtual wall), no. However, for real-time “Clash Detection” and remote collaboration where the office needs to see exactly what the worker sees without lag, a dedicated 5G-edge network is mandatory.

Q: How do you manage the “Motion Sickness” factor in VR?

A: We maintain a strict 90-FPS minimum. Motion sickness in VR is usually caused by a mismatch between visual input and inner-ear balance due to frame-rate drops. By using edge computing, we keep the experience smooth and nausea-free.

Q: Can these tools be used for retrofitting older buildings?

A: Yes. In fact, AR is arguably more valuable in retrofitting Brutalist architecture where original drawings are often lost. We scan the existing structure with LiDAR and use AR to project the new interventions directly onto the concrete.

Elevate Your Precision Workflow

The gap between AR vs VR construction is where the next decade’s profit margins will be found. At Nuvira Space, we don’t just use these tools; we design the architectural ecosystems that make them indispensable. By bridging the gap between the algorithmic and the physical, we ensure that every square meter of your project is optimized for performance, safety, and longevity.

Ready to transition from 2D limitations to 3D sovereignty? Connect with our Creative Technology team to audit your next project’s digital twin strategy.