Table of Contents

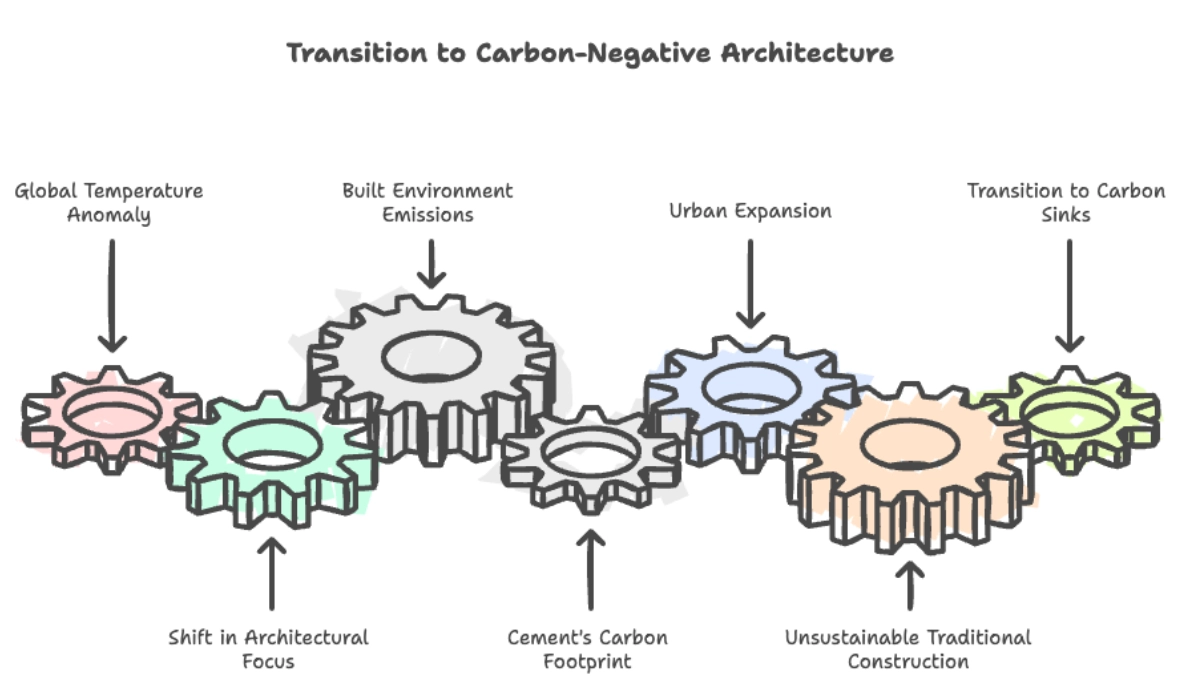

By 2026, the global temperature anomaly has surpassed 1.5 degrees Celsius for consecutive months, shifting the architectural conversation from “damage mitigation” to “atmospheric restoration.” The built environment accounts for nearly 40% of global emissions, with traditional Portland cement responsible for 8% of that total. As urban centers expand to house an additional 2,000,000,000 people by 2050, the math of traditional construction no longer holds. We are witnessing a phase shift where the very bones of our cities must transition from carbon sources to carbon sinks.

The Nuvira Perspective

At Nuvira Space, we view regenerative infrastructure not as a luxury tier of development, but as the only viable pathway for institutional stability. Our authority is built on the intersection of materials science and spatial psychology. We believe that a wall should do more than divide space; it should actively scrub the air, regulate thermal loads, and repair its own structural fatigue. This guide serves as your strategic roadmap for integrating carbon-negative concrete into high-performance projects, moving beyond the era of disposable architecture.

Technical Deep Dive: The Chemistry of Sequestration

Carbon-negative concrete achieves its status through two primary vectors: the replacement of traditional binders and the active mineralization of CO2 during the curing process. Unlike standard mixes that release 1 ton of CO2 for every 1 ton of cement produced, these advanced systems can sequester up to 250 kilograms of CO2 per cubic meter.

1. Mineral Carbonation and Biochar Integration

Modern carbon-negative mixes utilize bio-calcification and carbon-fortified aggregates. This is not merely “recycled” material; it is a fundamental reconfiguration of the concrete matrix.

- Biochar Loading: Incorporating 10% biochar by weight into the mix design increases the surface area for carbon bonding while reducing the overall weight of the slab by 15%. This biochar acts as a microscopic scaffold, providing housing for sequestered gases and improving the mix’s ductility.

- CO2 Injection: Direct injection of recycled CO2 into the wet-mix stage creates a permanent mineral (calcium carbonate). This increases compressive strength by 10% within the first 24 hours, allowing for faster formwork removal and a accelerated 12-month construction timeline.

- Binder Ratios: Transitioning from 100% Ordinary Portland Cement (OPC) to a 70/30 blend of Magnesium-based binders and fly ash reduces the embodied energy of the material by 60%. Magnesium oxide binders cure by absorbing CO2 from the atmosphere over their entire 50-year primary lifecycle.

2. The Mechanics of Self-Healing (Biocrete)

Self-healing properties are no longer experimental; they are a 2026 industry standard for high-rise foundations, bridge pilings, and marine infrastructure.

- Microbial Agents: Bacillus pseudofirmus spores are encapsulated in 2 millimeter clay pellets within the mix. These spores are extremophiles, capable of remaining dormant within the highly alkaline environment of concrete (pH 12 to 13) for up to 200 years.

- The Activation Trigger: When a crack exceeds 0.2 millimeters in width—a threshold that typically leads to rebar corrosion—moisture ingress dissolves the clay capsule. The bacteria “wake up,” consume the calcium lactate food source provided in the mix, and excrete limestone as a metabolic byproduct.

- Healing Capacity: These biological agents can seal cracks up to 0.8 millimeters wide, preventing the oxidation of internal steel rebar and extending the structural life of the building from 50 years to over 120 years. This effectively eliminates the need for expensive chemical resins or manual epoxy injections.

Comparative Analysis: Regenerative vs. Legacy Systems

When you evaluate materials, the “Initial Cost vs. Lifecycle Value” equation is the primary decision-making metric. Carbon-negative concrete currently carries a 12% to 18% price premium at the point of purchase, but the operational and maintenance savings shift the ROI significantly by year 10.

| Feature | Industry Standard (OPC) | Carbon-Negative (Nuvira Spec) | “So What?” (Spatial Implication) |

|---|---|---|---|

| Carbon Footprint | +900 kg CO2 / ton | -150 kg to -250 kg CO2 / ton | Your building becomes a certified carbon offset asset. |

| Thermal Mass | 0.28 Wh/kg·K | 0.42 Wh/kg·K | 30% reduction in HVAC cycling; more stable indoor temperatures. |

| Maintenance | Manual inspection/repair every 5-7 years | Autonomous repair; 25-year inspection cycles | Drastic reduction in tenant disruption and repair budgets. |

| Density | 2,400 kg/m3 | 2,050 kg/m3 | Lower dead load allows for 2 extra floors on the same foundation. |

| Fire Resistance | 240 mins (standard) | 360 mins (enhanced) | Lower insurance premiums and higher occupant safety. |

The Lived Experience: Thermal Mass and Sensory Impact

Choosing carbon-negative concrete isn’t just a spreadsheet victory; it dictates how a body feels within the space. The increased porosity of biochar-infused concrete acts as a natural humidity regulator. In a 300-square-meter office, this material can absorb and release moisture to maintain a consistent 45% to 55% relative humidity, reducing the “sick building syndrome” often associated with airtight, synthetic structures.

Furthermore, the acoustic dampening properties of these 20% lighter mixes are superior. The internal honeycomb structure of the sequestered carbon minerals breaks up sound waves, providing a 4 decibel reduction in ambient noise compared to the “echo-chamber” effect of standard industrial concrete. You are designing a space that is objectively quieter and more physiologically grounding. The tactile quality of the material—slightly warmer to the touch than standard OPC—removes the “cold-slab” clinical feeling common in modernism.

The Economics of Carbon Credits: Monetizing the Slab

In the 2026 fiscal landscape, a building’s carbon sequestering capacity is a liquid asset. Under current ESG (Environmental, Social, and Governance) frameworks, developers can trade the carbon sequestered in their foundations.

For a mid-sized commercial development utilizing 5,000 cubic meters of Nuvira-spec concrete, the project effectively traps 1,250,000 kilograms of CO2. At current market rates of $85 per ton of carbon credit, this generates a $106,250 upfront rebate or tradable credit. This financial buffer offsets the 15% material premium, often resulting in a “net-zero” cost increase before the building even breaks ground. You are essentially turning your structural requirements into an endowment for the building’s future.

Structural Integrity and Graphene Integration

We are currently seeing the first major deployments of Graphene-enhanced carbon-negative concrete. By adding 0.05% graphene by volume, the tensile strength of the concrete increases by 146%.

- Material Reduction: This allows structural engineers to reduce slab thicknesses from 200 millimeters to 140 millimeters without compromising safety.

- Elasticity: Graphene-enhanced concrete exhibits a higher Young’s Modulus, making it ideal for seismic zones where flexibility is as critical as rigidity.

- Conductivity: Beyond strength, graphene creates a conductive network within the concrete. This enables “Structural Health Monitoring” (SHM) where the building itself acts as a sensor, reporting stress points or moisture ingress to the facility manager’s dashboard in real-time via 1,000+ embedded nodes.

2030 Future Projection: The Autonomous City

By 2030, we anticipate buildings evolving further—pairing carbon-negative concrete cores with complementary systems like algae bio-curtains that transform glass facades into photosynthetic carbon sinks, creating fully regenerative envelopes. Early lab results show that adding 0.01% graphene to carbon-negative mixes allows the concrete to act as a massive battery. Imagine a residential tower where the 15,000 cubic meters of concrete in the core store solar energy gathered during the day, powering the building’s LED systems at night.

In this near-future, your building is not a static object; it is a sentient, self-repairing organism that pays for its own existence through energy generation and carbon credits. The transition from “building a structure” to “planting a city” will be complete. We will no longer demolish buildings; we will “hibernate” them as they continue to sequester carbon for centuries.

Comprehensive Technical FAQ

Q: Does carbon-negative concrete meet current building codes (IBC 2026)?

A: Yes. All Nuvira-spec materials meet or exceed ASTM C39 for compressive strength. In fact, the mineralization process often results in a 20% higher fire resistance rating (Class A1) because the material lacks the volatile organic compounds found in traditional additives. The carbon-negative matrix is naturally more refractory than OPC.

Q: How does the “self-healing” affect the aesthetic finish?

A: The healing process produces a slight white vein (calcite) where the crack once was. In the architectural community, these are being termed “structural scars”—a visible sign of a building’s resilience that adds a unique, organic texture to off-form concrete finishes. It tells a story of survival and adaptation.

Q: Can this be used in 3D Printing applications?

A: Absolutely. The 2026 “Bio-Print” mix is optimized for extrusion. It sets 30% faster than standard mortar, allowing for 4-meter vertical spans to be printed without support structures, drastically reducing labor costs by 40%. The inclusion of carbon-fibers in the print-mix ensures that the layers bond at a molecular level, eliminating cold joints.

Q: What is the impact on the supply chain?

A: By utilizing local biochar and industrial byproducts, you reduce the transport distance of raw materials. Typically, 85% of the components are sourced within a 200-kilometer radius of the site, significantly lowering the “Scope 3” transport emissions. This also insulates your project from global logistical shocks.

Q: Is it compatible with recycled steel or basalt rebar?

A: It is highly optimized for Basalt Fiber Reinforced Polymer (BFRP) rebar. Since basalt rebar cannot rust, and carbon-negative concrete heals its own cracks, this combination creates a “perpetual structure” that requires zero maintenance for 100+ years.

Transitioning to a Carbon-Negative Future

The shift to regenerative infrastructure is an inevitability driven by both climate reality and economic pressure. You are no longer just an architect, developer, or designer; you are a steward of the carbon cycle. By specifying carbon-negative, self-healing materials, you ensure that your projects remain relevant, resilient, and valuable in a post-carbon economy.

Regenerative design is not about doing “less bad”; it is about doing “more good.” When you pour a Nuvira-spec foundation, you are planting a forest of stone.

Take the Lead in Regenerative Infrastructure

Contact Nuvira Space today to receive a customized Material Lifecycle Analysis for your next project. Let us help you turn your structural requirements into environmental solutions.