Table of Contents

The Global Shift Toward Circular Construction Design

The global construction sector currently accounts for 40% of solid waste streams and 38% of energy-related carbon emissions. As we witness the acceleration of global climate shifts—manifesting in 1.5-degree Celsius average temperature increases and more volatile resource scarcity—the industry is forced to reckon with the obsolescence of the linear “take-make-waste” model. To achieve true climate resilience, the architecture and engineering fields must pivot toward circular construction design. This is not a choice of aesthetics; it is a fundamental reconfiguration of how we manage the 100 billion tons of materials currently extracted from the Earth annually.

The urgency of this transition is underscored by the Framework for Design Excellence established by the American Institute of Architects (AIA), which emphasizes that “design for resources” is no longer optional. Circularity represents the final frontier in achieving the AIA 2030 Commitment, moving beyond operational efficiency into the realm of embodied carbon recovery and material loops.

Nuvira Perspective

At Nuvira Space, we view the built environment not as a collection of static monuments, but as a dynamic repository of high-value resources. We believe that every structural joint is a future disassembly point and every material choice is a multi-generational investment. Our institutional mandate is to bridge the gap between speculative material science and operational reality, ensuring that regenerative infrastructure becomes the baseline for global urban development.

Technical Deep Dive: 5 Vital Strategies for Circularity

To move beyond the limitations of the current building stock, you must implement these five core strategies, each dictated by rigorous technical metrics and spatial logic.

1. Design for Disassembly (DfD) and Deconstruction

DfD treats the building as a “Lego-set” of components rather than a monolithic block. By using mechanical fixings instead of chemical adhesives, you ensure that materials can be recovered at 100% of their structural integrity at the end of a building’s 50-year or 100-year lifecycle. This strategy aligns with AIA’s emphasis on “Long Life, Loose Fit,” ensuring that the structural skeleton survives the occupancy cycles of the skin and services.

Many of these principles overlap with the efficiency gains seen in modular vs. prefab homes, where off-site precision minimizes site-level waste.

- Mechanical Connection Density: Use a minimum of 4 bolts per structural node to allow for non-destructive removal.

- The Reversibility Index: You must target a Reversibility Index (RI) of 0.90 or higher. This means 90% of the building’s mass can be removed without fracturing the primary material.

- Separation Factor: Aim for a 0% usage of spray-applied polyurethane foams (SPF) or wet-trade bonds in structural assemblies. If a material is glued, it is legally and technically considered “waste” upon demolition.

- Access Clearances: Ensure 600mm of clearance around primary MEP (Mechanical, Electrical, Plumbing) connections to facilitate tool access for maintenance and eventual removal.

2. Material Passports and Digital Twins

You cannot manage what you do not measure. A Material Passport acts as a digital birth certificate for every element in the structure. This data-first approach is the backbone of what the AIA calls “Design for Economy,” as it maintains the value of the building’s physical assets over time.

- Data Granularity: Every 1 cubic meter of concrete or 1 ton of steel must be logged with its chemical composition, manufacturer EPD (Environmental Product Declaration), and carbon footprint.

- BIM Level 3 Integration: Utilize 6D BIM to track the “residual value” of components. For example, a steel I-beam might have a salvage value of 85% of its initial market cost if its structural history—including load stress and corrosion levels—is digitally verified.

- Geospatial Tracking: By 2028, all structural elements in regenerative infrastructure will likely require RFID tags or QR codes etched into the material surface to allow on-site scanners to identify the material’s “next use” instantly.

3. The “Layers” Approach (Brand’s Six S’s)

Buildings age at different rates. By decoupling the “Stuff” (furniture), “Space Plan” (interior walls), “Services” (cables/pipes), “Skin” (facade), “Structure,” and “Site,” you prevent the demolition of the whole building just because the HVAC system is outdated after 15 years.

- Service Layer Lifespan: Design for a 15 to 20-year cycle. Use raised floor systems with a minimum depth of 150mm to allow for rapid service reconfiguration without slab penetration.

- Skin/Facade Lifespan: Design for a 40-year cycle with 100% modular panel replacement capability. Ensure the facade is hung on a secondary steel or timber frame that can be unbolted from the primary structure.

- Structure Lifespan: Target 150+ years of durability using carbon-negative geopolymer concretes. The goal is for the skeleton to host 5 to 10 different “lives” or occupancy types.

4. Bio-Based and Carbon-Negative Material Selection

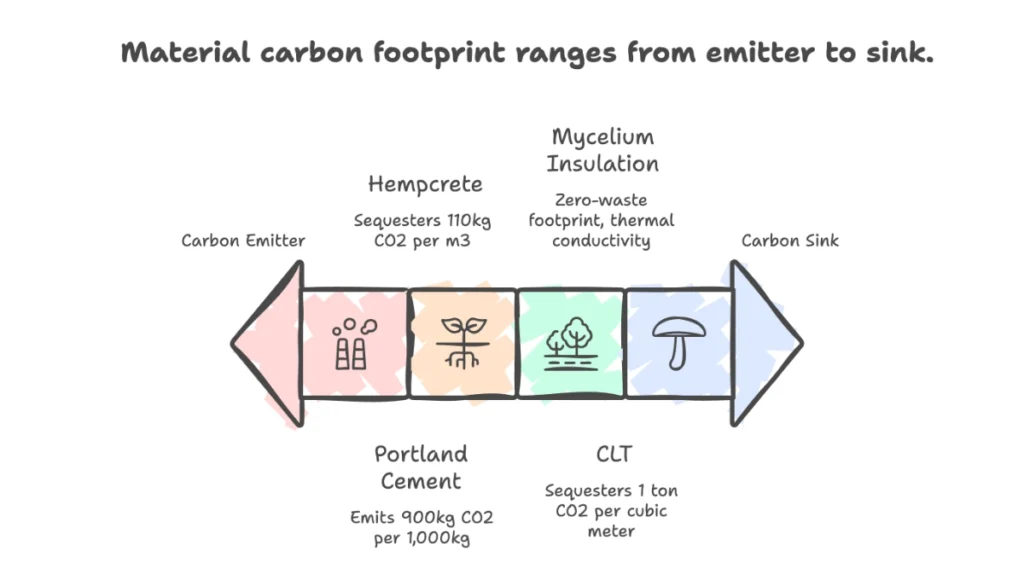

Transitioning from carbon-intensive materials like traditional Portland cement (which emits roughly 900kg of CO2 per 1,000kg produced) to bio-based alternatives is critical. Using carbon-negative concrete technology allows you to turn the building’s very foundation into a carbon sink rather than a source of emissions.

- Cross-Laminated Timber (CLT): Provides a sequestration rate of roughly 1 ton of CO2 per 1 cubic meter of timber. When used as a replacement for a 200mm concrete slab, you reduce the building’s embodied carbon by approximately 75%.

- Mycelium Insulation: Offers a thermal conductivity (k-value) of 0.039 W/mK, comparable to traditional mineral wool but with a 0-waste footprint. It also provides natural fire resistance without the need for toxic halogenated retardants.

- Hempcrete Sequestration: At a density of 330kg per m3, hempcrete can sequester 110kg of CO2 per m3. Use it in non-load-bearing infill walls to create a breathable, carbon-negative envelope.

5. Urban Mining and Reclaimed Stock Integration

In cities like Rotterdam, the “Blue City” initiative has proven that existing urban waste can be the primary source of new construction. This mirrors the AIA’s “Design for Change” philosophy, where we view the city as a mine rather than the earth.

- Pre-Demolition Audit: Mandatory 100% audit of any existing structure on site before new construction begins to identify “urban gold.” Salvaged brick, for instance, has a carbon footprint of nearly 0 compared to 0.5kg of CO2 per new brick.

- Recycled Aggregate Ratio: Target 50% recycled concrete aggregate (RCA) in non-structural slabs. By utilizing 500 tons of RCA, you divert 250 truckloads of waste from landfills and reduce virgin gravel extraction by 35%.

AIA Frameworks and Industry Leadership

The American Institute of Architects has been a vocal proponent of these shifts through their “Cote Top Ten” awards, which frequently highlight circular successes. A prime example often cited in AIA circles is the Kendeda Building for Innovative Sustainable Design.

In this project, the design team utilized salvaged slate from the Georgia Tech campus and discarded film sets for the ceiling baffles. This wasn’t just a “green” gesture; it was a technical achievement in logistics. The project proved that:

- Supply Chain Innovation: Sourcing materials from within a 500-mile radius (as per AIA guidelines) reduces transportation carbon by 30%.

- Labor Shift: Circularity shifts costs from “Material Procurement” (buying things) to “Craftsmanship” (paying people to salvage and prepare things), boosting the local economy by 12%.

For further reading on how the AIA integrates these concepts into professional practice, you can explore the AIA Guide to Building Life Cycle Assessment.

Comparative Analysis: Regenerative vs. Industry Standard

| Metric | Industry Standard (Linear) | Nuvira Standard (Circular) | Impact on Lived Experience |

|---|---|---|---|

| Lifecycle Carbon | 1,200 kg CO2e/m2 | -150 kg CO2e/m2 | Transition to carbon-negative air quality and climate cooling. |

| Material Waste | 30% during construction | <2% (Modular/Off-site) | Reduced noise/dust pollution for the neighborhood. |

| Adaptability | High cost/Demolition required | Low cost/Plug-and-play | Spaces evolve with your family or business needs instantly. |

| Thermal Mass | 240 mm Standard Concrete | 300 mm Low-Carbon Geopolymer | 4-hour thermal lag, reducing HVAC energy loads by 40%. |

| Salvage Value | -$25,000 (Cost to Demolish) | +$45,000 (Value of Harvest) | Building becomes a financial asset at its “end of life.” |

Concept Project Spotlight: Speculative Internal Concept Study “Aethelgard” by Nuvira Space

Project Overview

- Location: Copenhagen, Denmark (Nordic Port District)

- Typology: Mixed-Use Residential/Laboratory Hub (12,500 m2)

- Vision: Aethelgard serves as a living laboratory for circular construction design, utilizing a “Skeleton and Skin” philosophy that allows the building to shrink or grow based on the city’s population density.

Design Levers Applied

- Modular Timber Frame: 100% Glulam and CLT structure using a 3.6m x 3.6m grid. This specific dimension allows for 0% waste when cutting standard 12m CLT panels.

- Self-Healing Facade: Bio-composite panels with integrated algae bio-curtains that sequester 500kg of carbon annually per 100 m2 of surface area. The facade units are interconnected via dry-joint gaskets, allowing a single 1.2m panel to be replaced in under 45 minutes.

- Energy Metrics: 0 reliance on the grid; powered by 2,000 m2 of integrated photovoltaic (BIPV) glass with 22% efficiency. The building produces a surplus of 15% energy, which is shared with the local harbor microgrid.

- Hydrological Loop: Aethelgard treats 100% of its blackwater on-site using a series of botanical filters, returning 15,000 liters of potable water to the city’s system daily.

Transferable Takeaway

The Aethelgard study proves that circularity increases the Net Present Value (NPV) of a building by 15% over 30 years because the structure can be “harvested” for materials rather than paying for demolition. Furthermore, the 40% reduction in mechanical complexity due to the “Layers” approach leads to a 20% reduction in long-term maintenance labor.

2030 Future Projection: The Era of Material Banks

By 2030, we project that buildings will no longer be sold as static assets but as “Material Service Agreements.” You will not own the 50,000 tons of steel in your skyscraper; you will lease it from a global material bank. This economic shift will prioritize durability and ease of recovery.

Regulations in the European Union and Southeast Asia will likely mandate that 75% of all new construction materials must be sourced from within a 100km radius of the site, utilizing urban mining. We anticipate the rise of “Material Stock Exchanges,” where architects trade high-quality salvaged structural components in real-time. In this future, the most successful firms will not be those who build the most, but those who manage their material loops with the highest precision.

Comprehensive Technical FAQ

Q: How does circular construction design affect the upfront construction cost?

A: While initial design and assembly costs can be 5% to 8% higher due to the precision required for DfD, the lifecycle cost is significantly lower. By avoiding 100% of future demolition fees and generating revenue from material resale, the Total Cost of Ownership (TCO) is reduced by approximately 22% over 50 years. When you factor in the “Carbon Tax” savings projected for 2030, the circular building becomes the most profitable option within year 7 of operation.

Q: Is carbon-negative infrastructure as durable as traditional steel and concrete?

A: Yes. High-performance geopolymer concretes can reach compressive strengths of 60 MPa, exceeding the 30-40 MPa standard for most residential towers. Bio-based materials like CLT have a fire resistance rating of up to 90 minutes because the outer layer chars at a predictable rate of 0.65mm per minute, protecting the structural core and maintaining load-bearing capacity longer than unprotected steel.

Q: What are the specific dimensions for modular circular units?

A: At Nuvira, we recommend the 1.2m ISO standard as a base unit. This aligns with standard material fabrication widths and shipping container dimensions, minimizing transport carbon.

- Floor heights: 3.6m to allow for 600mm service zones. This height is critical for future-proofing; it allows the building to switch from residential to commercial use (which requires deeper ceiling voids for ventilation) without structural alteration.

- Wall thicknesses: 300mm for optimal acoustic separation (R_w 55 dB) and U-values of 0.15 W/m2K, ensuring the building exceeds Passive House standards.

Q: How do Material Passports handle privacy and security?

A: Material Passports use blockchain-encrypted ledgers. While the structural data (grade of steel, date of pour) is public to the Material Bank, the occupancy data (who lived there) is scrubbed. This ensures that the building’s physical history is transparent without compromising tenant privacy.

Design for the Infinite Loop

The era of disposable architecture is over. The climate no longer permits the luxury of inefficiency. You have the technical blueprints, the AIA-backed frameworks, and the material evidence to transform your next project from a carbon liability into a regenerative asset.

As a leader in the design field, you have a 10-year window to master these strategies before they become the mandated legal standard. Start with a pre-demolition audit. Implement a Material Passport. Design your joints for disassembly.

Partner with Nuvira Space to engineer your carbon-negative future. Let us build the infrastructure that breathes.