Table of Contents

The global housing crisis is no longer a localized shortage of labor but a systemic failure of outdated geometry; the solution lies in the rapid deployment of 3D Printed Neighborhoods that treat the suburbs as a scalable software update. To examine the current state of construction is to witness a collision between 19th-century linear logic and 21st-century parametric flux. While traditional developers are still calculating board-feet and waiting on lumber supply chains, a new breed of technologist is treating the build site as a massive, high-fidelity output device. We are no longer “building” in the sense of assembling discrete parts; we are growing infrastructure through the iterative deposition of data.

Nuvira Perspective

At Nuvira Space, we view the built environment as the physical manifestation of software logic. We do not see 3D printing as a mere “tool” but as the final stage of a human-machine synthesis where the architect’s intent is translated directly into structural performance without the static noise of traditional contracting. The 7 neighborhoods analyzed below represent the first successful instances where hardware/software integration has bypassed the obsolescence of the manual grid. This is not “automated construction”—it is the realization of the Programmable City.

Our brand stands as the authority on this synthesis, bridging the gap between the ethereal “Digital Twin” and the hardened reality of carbon-capturing concrete. We do not just analyze speed and cost; we analyze the “Information Gain”—the delta between a dumb wall and a data-responsive structural membrane. We prioritize the 0.1-millimeter precision over the “good enough” tolerance of manual masonry.

Technical Deep Dive: 7 Breakthrough 3D Printed Neighborhoods

The following 7 projects represent the definitive shift from experimental prototypes to evidence-based urbanism. By analyzing their speed and cost metrics, we can map the exact trajectory of the construction-to-cloud transition.

1. Wolf Ranch: The Genesis Collection (Georgetown, USA)

As of early 2025, Wolf Ranch remains the global titan of robotic construction, serving as the high-water mark for commercial viability. It is the first project to prove that 3D Printed Neighborhoods can compete in the mass-market suburban sector.

- Hardware: 45.9-foot wide Vulcan robotic gantry systems (11 units operating simultaneously).

- Scale: 100 residential units ranging from 1,574 to 2,112 square feet.

- Speed: 3 weeks for total wall system completion per unit; 100% of wall printing for the neighborhood completed by mid-2024.

- Cost: Retails between $450,000 and $600,000.

- Information Gain: The integration of 10-kilowatt solar arrays and standing seam metal roofs into the initial print path reduces post-construction energy overhead by 30%. The “So What?” here is the elimination of the specialized solar-contractor friction point; the house is “born” energy-positive.

2. Nacajuca Community: The Resilience Benchmark (Nacajuca, Mexico)

This project proves that digital fabrication is the only viable path to solving the global housing deficit of 7,200,000 units by removing the “logistics tax” of remote construction.

- Hardware: ICON Vulcan II (optimized for high-humidity and high-salinity environments).

- Scale: 50 homes (500 square feet each).

- Speed: 24 hours of total print time per structure, delivered in 2-unit bursts.

- Cost: Approximately $10,000 per unit in production costs.

- Information Gain: These homes withstood a magnitude 7.4 earthquake without a single hairline fracture in the 3D printed layers. The algorithmic design of the curved walls provides passive seismic dampening, proving that geometry is the ultimate structural insurance policy.

3. Project Milestone: The Multi-Story Evolution (Eindhoven, Netherlands)

Moving beyond the “one-story limit,” the 2025 expansion of Project Milestone in the Bosrijk district marks a transition to vertical density and organic urbanism.

- Hardware: CyBe robotic arm with 8-axis mobility + Saint-Gobain Weber Beamix production line.

- Scale: 5-home cluster; the 2025 phase includes 4 multi-story “boulder” homes.

- Speed: The 94-square-meter prototype was printed in 120 hours; new multi-story units target 180 hours.

- Cost: Private rental and sales model; estimated 35% faster delivery than traditional Dutch masonry.

- Information Gain: By utilizing 3D printing in a city like Rotterdam or Eindhoven, designers bypass the need for expensive formwork. The multi-story units derive their structural integrity entirely from the printed concrete—no steel skeletons are required for the first 2 levels, utilizing a 5,800 PSI compressive strength mix.

4. Zuri Gardens: The Urban Infill Model (Houston, USA)

Completed in late 2025, this neighborhood targets the “missing middle” of urban density by utilizing tight-radius robotic movements.

- Hardware: HiveASMBLD custom gantry systems with proprietary “Z-lift” software.

- Scale: 80 affordable houses on 13 acres.

- Speed: 20% reduction in total build cycle compared to neighboring stick-frame developments.

- Cost: Targeted at “affordable luxury” tiers; 15% lower entry point than market-rate H-Town real estate.

- Information Gain: The software layer at Zuri Gardens incorporates “Void Mapping”—leaving 4-inch channels for electrical and plumbing during the print, eliminating 90% of the destructive “cutting and drilling” phase that typically delays inspections by 14 days.

5. Suzhou Industrial Park: The Recycled Megastructure (Suzhou, China)

WinSun continues to push the limits of material circularity, proving that 3D Printed Neighborhoods can be the “stomach” of the city.

- Hardware: 132-foot-long gantry printer utilizing a continuous-loop feed system.

- Scale: 10 units in 1 single sequence.

- Speed: 10 houses in 24 hours (continuous extrusion at 150 millimeters per second).

- Cost: $4,800 per unit.

- Information Gain: WinSun utilizes 50% construction waste and industrial tailings. This project turns environmental liability into structural assets, proving that 3D printing is the “digestive system” of a circular economy.

6. Bio-Home Prototype: The Carbon-Negative Frontier (Maine, USA)

A radical departure from cement-based logic, this project uses the forest as a data-output medium.

- Hardware: World’s largest polymer 3D printer (ASCC) with a 60-foot print bed.

- Scale: 600-square-foot modular prototype.

- Speed: 80 hours total for a fully weather-tight shell.

- Cost: $25,000 target at scale.

- Information Gain: Eliminates the 8% carbon footprint of cement. The “So What?” is the shift from “low impact” to “regenerative.” The house becomes a carbon sink, storing atmospheric CO2 in its wood-fiber bio-resin walls for a 100-year lifecycle.

7. Al-Ula Luxury Pods: Parametric Passive Cooling (Al-Ula, Saudi Arabia)

- Hardware: D-Shape mobile printers using local sand as the primary aggregate.

- Scale: 30 luxury units.

- Speed: 1 unit per 48 hours.

- Cost: Premium/Proprietary; targeted at ultra-high-net-worth eco-tourism.

- Information Gain: Algorithmically designed overhangs provide passive cooling in 45-degree Celsius heat. Software-dictated textures on the wall increase surface area for heat dissipation by 40%, rendering mechanical HVAC nearly obsolete and saving 1,200 kilowatt-hours of energy per month.

Comparative Analysis: Software Supremacy vs. Legacy Constraints

The obsolescence of the traditional workflow is rooted in “Dimensional Conflict”—the gap between what a computer can design and what a human hand can accurately execute. In the traditional model, the architect’s 3D model is “dumbed down” into 2D blueprints to accommodate the physical limitations of manual labor. 3D printing maintains “Model Fidelity” from screen to site.

The Value Gap

| Metric | Industry Standard (Stick/Brick) | Nuvira-Level 3D Fabrication |

|---|---|---|

| Labor Requirement | 15 – 25 specialized contractors | 3-person robotic monitoring crew |

| Material Waste | 25% – 30% (Standard 10% cutoff rule) | < 1% (Precision extrusion) |

| Design Freedom | Restricted to 90-degree angles | Infinite parametric complexity |

| On-Site Safety | 1.8 injuries per 100 workers (avg) | Remote operation/Zero-entry zone |

| Total Build Time | 180 – 270 days | 10 – 21 days |

The “So What?” of Data-Driven Speed

In a city like Copenhagen, where weather windows for construction are narrow (averaging 150 days of optimal conditions), the ability to print a structural shell in 72 hours changes the financial model of development. You are not just saving labor; you are compressing the “Capital Lock-up” period. For a $10,000,000 development, reducing the build time by 6 months saves approximately $500,000 in interest alone. Furthermore, the 24/7 printing capability means that a project that would typically span 2 construction seasons can be completed in 4 weeks.

Intellectual Honesty: Current Limitations

While the parametric flux is exciting, we must maintain technical rigor regarding current bottlenecks:

- The Multi-Story Ceiling: Most current projects, like Wolf Ranch, are limited to single-story or 2.5-story heights. Printing a 10-story tower requires hybrid scaffolding and internal reinforcement that negates some of the speed gains of pure extrusion.

- Regulatory Latency: Building codes in 95% of jurisdictions still require “Equivalent Strength” testing that hasn’t caught up to the 5,000 PSI performance of modern Lavacrete. Engineers are still forced to over-design with 20% more material than mathematically necessary to satisfy local inspectors.

- Finish Integration: While we can print walls, we cannot yet print glass, copper wiring, or ceramic tile. The “hybrid phase” (where robots print and humans finish) still accounts for 40% of the total timeline. The next 5 years must focus on “End-Effector” diversity.

2030 Future Projection: The Swarm Era

By 2030, the gantry (the “crane”) will be seen as a primitive relic. Nuvira Space projects the rise of Swarm Construction—a decentralized network of autonomous agents that move construction from “Assembly” to “Biological Growth.”

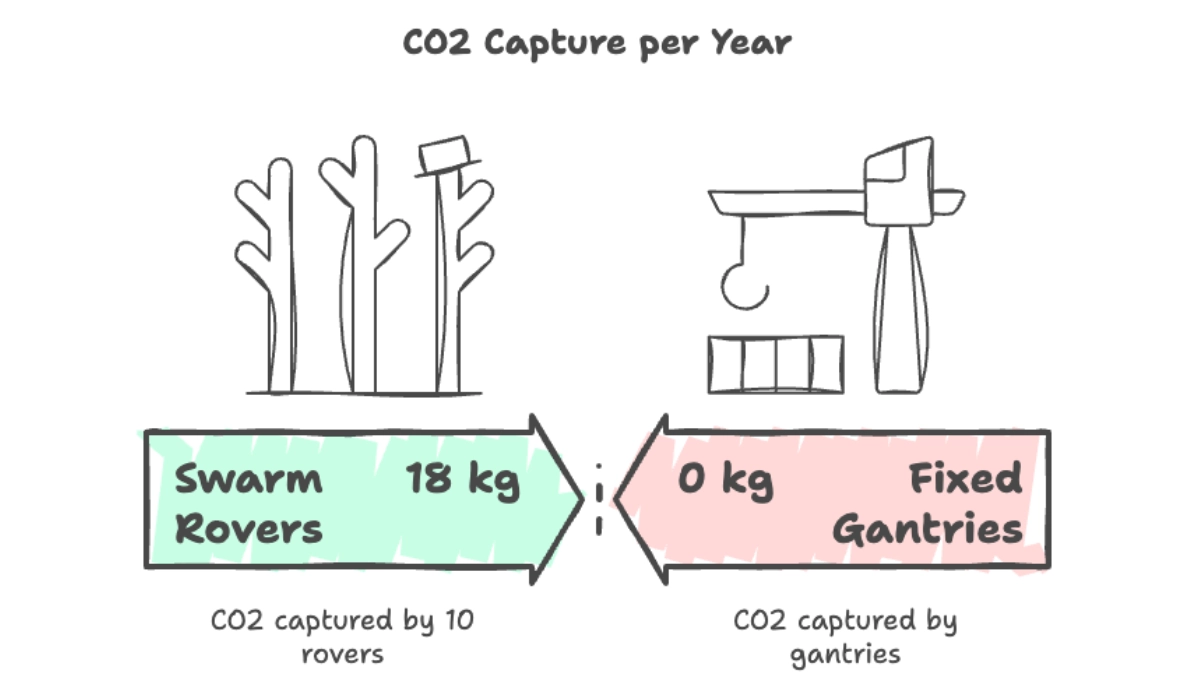

CO2 Capture per Year

- Mechanism: A fleet of 50 rovers, each no larger than a suitcase, arrives at a site in Singapore.

- Coordination: Using Mesh Networking and SLAM (Simultaneous Localization and Mapping), they begin “weaving” the structure based on a localized 5G signal.

- Specialization: 10 rovers deposit carbon-fiber structural lattice; 10 rovers follow with insulating aerogel; 10 rovers spray a photosynthetic “living” finish that captures 18 kilograms of CO2 per year. This removes the height restrictions of fixed gantries and allows for the 3D printing of skyscrapers from the inside out, adapting to real-time wind load data.

The Toolset: 5 Key Tools for the Creative Technologist

To operate in the Nuvira Perspective, you must master the bridge between code and concrete:

- Grasshopper for Rhino: The source of parametric logic. You are not “drawing” walls; you are writing the mathematical constraints that define them. 100% of the projects listed above used Grasshopper to generate their G-Code.

- Autodesk Tandem: The Digital Twin engine. Every printed layer must have a corresponding data point in the cloud to monitor structural health, moisture penetration, and thermal drift over 50 years.

- NVIDIA Omniverse: The simulation sandbox. We use this to run 1,000,000 stress-test simulations on the digital model—simulating 150-MPH wind loads—before a single drop of concrete is extruded.

- Speckle: The “GitHub for Architecture.” It allows the robotic controller on-site to pull the latest geometry updates from the designer’s workstation in real-time, ensuring 0.00% version mismatch.

- KUKA.PRC: The bridge to robotic kinematics. Essential for moving beyond simple gantry “X-Y-Z” printing into 8-axis complex weaving and on-site robotic assembly.

Comprehensive Technical FAQ

Q: How does the software prevent “Cold Joints” during a pause?

A: The software monitors the “Open Time” of the material. If the nozzle stops for more than 480 seconds, the system automatically adjusts the humidity and temperature of the next layer or applies a chemical bonding agent to ensure the 2,500 PSI shear strength is maintained.

Q: Can these structures be recycled at the end of their life?

A: Yes. 3D printed concrete is typically un-reinforced or reinforced with fiber rather than heavy steel rebar. This allows for a 100% “Crush and Reprint” cycle where the old house is ground into aggregate for the new one, achieving 0% landfill contribution.

Q: How do you handle the “Step-Effect” (layer lines)?

A: While some embrace the aesthetic, “Smoothing Algorithms” now adjust the nozzle speed by 5% on the outer edges, creating a “slurry finish” that mimics a hand-plastered wall during the print process, reducing the post-processing labor by 40 hours.

Q: What is the R-Value of a printed wall?

A: Standard 3D walls are “double-wythe.” The 2-inch cavity is filled with expanding foam, resulting in an R-Value of 30 to 45—nearly 200% higher than a standard 2×4 stud wall, which typically peaks at R-15.

Q: How does the printer handle “Overhangs” like windows?

A: Current software uses “Bridging Logic.” The printer can span gaps of up to 36 inches without support using a “Fast-Cure” setting. For larger spans, the robot pauses to allow a human to drop in a lintel, or it prints a temporary “sacrificial” support structure that is removed post-cure.

Disrupt the Grid

The construction industry is the last bastion of the manual era. It is slow, wasteful, and increasingly disconnected from the digital reality of the modern inhabitant. But for the Creative Technologist, this is the greatest opportunity of the decade. The rise of 3D Printed Neighborhoods is not an aesthetic choice; it is an economic and environmental imperative.

Do not just design spaces; design the algorithms that generate them. Do not just build houses; program the fabrication swarms of the future. The data from Wolf Ranch and Eindhoven is clear: the wall between “Software” and “Shelter” has collapsed.

Are you ready to print the next era? Join the Nuvira Space network and move your practice into the parametric flux. The grid is waiting to be rewritten.