Table of Contents

The era of the “static blueprint” has collapsed. As you walk through the construction sites of 2026, you are no longer witnessing a linear assembly of standardized parts. Instead, you are seeing robotic fabrication architecture move from experimental laboratory prototypes to the core of the global infrastructure machine. The traditional workflow—where an architect draws a line, a contractor interprets it, and a laborer manually executes it—is being replaced by a closed-loop digital thread.

Nuvira Perspective

At Nuvira Space, we view the building not as a finished object, but as a high-fidelity data output. We believe that human-machine synthesis is the only viable response to the compounding crises of labor scarcity and material waste. By offloading repetitive cognitive and physical loads to autonomous systems, we liberate the architect to focus on spatial intelligence and atmospheric quality. We don’t just build with robots; we evolve the vocabulary of shelter through algorithmic precision.

1. Real-Time Adaptive Kinematics: The Death of the Tolerance Gap

Traditional construction relies on “tolerances”—the small margins of error where human hands inevitably deviate from the CAD model. In 2026, robotic fabrication architecture has eliminated the tolerance gap through closed-loop feedback.

The Technical Shift

Using 6-axis and 7-axis robotic arms equipped with LiDAR sensors, the hardware now performs “scan-to-path” adjustments every 20 milliseconds. If a sub-surface is uneven by even 2.5 millimeters, the robot’s toolpath recalibrates in real-time. This level of responsiveness is critical when deploying circular construction design principles, where irregular, reclaimed materials must be integrated into new structural grids.

- Hardware: KUKA KR QUANTEC-2 or ABB IRB 6700-series industrial arms.

- Sensor Array: 360-degree laser scanners and high-torque force sensors.

- Information Gain: You are moving from “predictive” building to “reactive” fabrication.

The AIA Perspective on Technical Competency

According to recent AIA (American Institute of Architects) foresight reports, the role of the “Architect of Record” is shifting toward “Architect of System.” The AIA emphasizes that the mastery of these robotic toolpaths is no longer a niche skill but a fundamental requirement for maintaining professional liability in an era of automated assembly.

2. Multi-Material Extrusion: Beyond the 3D Printed Shell

The 1st generation of 3D printing was limited to “contour crafting” with concrete. Today, you are utilizing multi-material end-effectors that can switch between high-performance polymers, bio-composites, and ultra-high-performance concrete (UHPC) within a single continuous print job.

Spatial Value

By varying the density of a wall’s infill from 15% to 85% based on structural load, you create a “graded” materiality. This allows for integrated HVAC channels and electrical conduits to be printed directly into the structure, removing the need for 3rd-party subcontractors to drill into finished walls. This additive approach is the backbone of modern 3d printed neighborhoods, where entire blocks are extruded with zero structural excess.

- Material Specs: UHPC tensile strength exceeding 15 MPa; Bio-polymer elasticity ratings calibrated for seismic zones.

- Thermal Performance: Integrated “dead-air” pockets within 3D-printed layers provide R-values of 35 or higher without separate insulation.

3. Swarm Assembly in Extreme Topographies

In cities like Singapore, where land is at a premium and construction sites are vertically constrained, the shift has moved toward Mobile Swarm Robotics. Instead of one giant gantry, you are deploying 12 to 15 autonomous, wheel-based robots that collaborate on a shared coordinate system.

- Logistics: 100% autonomous navigation via SLAM (Simultaneous Localization and Mapping).

- Efficiency: 24-hour operation cycles with 0 downtime for shift changes.

- So What? This allows for “in-situ” fabrication in dense urban cores without the 40% logistical overhead of transporting oversized prefabricated modules.

The coordination of these swarms mimics the efficiency of urban rewilding examples, where decentralized agents work in harmony to restore a complex ecosystem. In construction, this decentralization means that a failure in 1 robot does not stop the entire site; the remaining units simply re-allocate the workload.

4. Generative Timber Joinery: The Digital Carpenter

Mass timber is no longer about simple CLT panels. You are now using robotic milling to create “Complex Reciprocal Frames.” By using 5-axis CNC milling heads on robotic arms, you can produce 1,200 unique timber joints for a single roof structure, each with a 0.1-millimeter fit.

Algorithmic Craftsmanship

This isn’t just about speed; it’s about structural honesty. Robotic milling allows for “integral joinery”—wood-to-wood connections that eliminate the need for 200 kilograms of steel plates and bolts in a typical residential frame. The software calculates the fiber direction of each timber piece, ensuring the robot cuts along the path of maximum structural integrity.

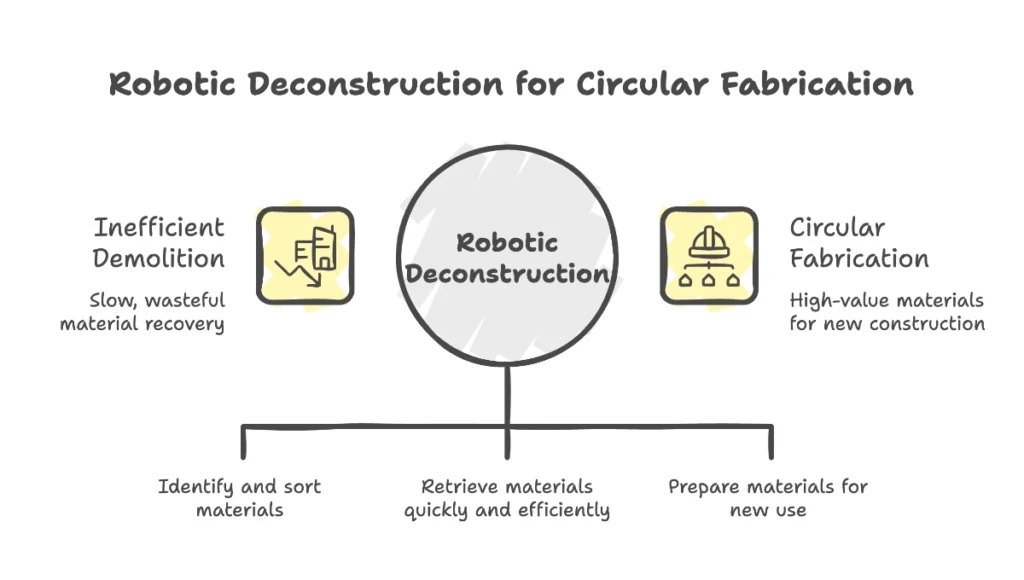

5. Circular Fabrication: Robotic Deconstruction

The boldest shift in 2026 isn’t how we build, but how we un-build. Robots are now programmed with “Computer Vision for Sorting,” allowing them to identify, extract, and re-mill 95% of materials from a 50-year-old structure to be reused in a new robotic toolpath.

- Vision System: Neural networks trained on 1,000,000+ images of construction debris.

- Recovery Rate: Retrieval of copper, steel, and high-quality timber at 4 times the speed of manual salvage.

- Macro Impact: This closes the loop on the “Cradle-to-Cradle” philosophy, turning every demolition site into a high-value quarry for new construction.

Comparative Analysis: Digital Thread vs. Traditional Fragmentation

| Feature | Industry Standard (Traditional) | Nuvira Solution (Robotic Fabrication) |

|---|---|---|

| Design Intent | Static 2D/3D Files | Parametric Live-Data |

| Labor Cost | 45-60% of Total Budget | 12-18% (Hardware/Ops) |

| Material Waste | 25-30% Average | < 3% (Optimized Toolpaths) |

| Assembly Speed | Linear / Subject to Weather | Exponential / 24-7 Capability |

| Quality Control | Visual Inspection Post-Facto | Real-time Sensor Validation |

Speculative / Internal Concept Study: NEXUS-01 by Nuvira Space

Project Overview

- Location: Copenhagen, Denmark (Harbor District)

- Typology: Mixed-Use Research Hub / Vertical Urban Farm

- Vision: A self-optimizing structure that grows its own envelope using locally sourced bio-materials and robotic weaving.

Design Levers Applied

- Robotic Carbon Fiber Weaving: Using 2 synchronized KUKA arms to weave a structural skin that weighs 80% less than steel but handles 3 times the tensile load.

- In-Situ Soil Printing: The base of NEXUS-01 utilizes a 3D-printed earth mixture from the harbor excavation, stabilized with 5% bio-resin. This mirrors the sustainable ethos of urban earthships, but scales it for high-density urban living.

- Dynamic Lighting Integration: 4,500 embedded LED nodes placed during the robotic layup process, controlled by an AI that tracks solar gain.

Transferable Takeaway

NEXUS-01 proves that robotic fabrication architecture allows us to treat “site-specific soil” as a high-tech building material, drastically reducing the carbon footprint of transport logistics. It moves the conversation from “pre-fabricated” to “locally-processed.”

Intellectual Honesty: Current Limitations

Despite the momentum, we face 3 primary bottlenecks:

- Regulatory Lag: Building codes in 90% of global territories do not yet recognize robotic toolpaths as “certified” structural signatures. While the AIA is advocating for new standards, the current path to approval requires 200% more documentation than traditional methods.

- Hardware Fragility: Industrial robots are designed for clean factory floors; 20% of hardware failures occur due to dust and humidity on active construction sites.

- Data Interoperability: Moving 500GB of real-time sensor data from a site to the cloud requires 5G infrastructure that is not yet universal.

2030 Future Projection

By 2030, the “Robot” will disappear into the “Building.” We anticipate the rise of Self-Fabricating Buildings, where the maintenance drones used during construction remain as permanent “immune systems,” repairing 3D-printed surfaces and upgrading modular interior components autonomously. The structure will no longer be a finished product, but a living, evolving entity.

The Toolset: 5 Key Tools

- Grasshopper/Rhino: The foundational parametric engine for geometry generation.

- HAL Robotics: For translating complex geometries into machine-readable code.

- Nvidia Isaac Sim: For high-fidelity robotic simulation and synthetic data generation.

- OpenCV: For real-time computer vision during the assembly phase.

- Fologram: For Mixed Reality (AR) supervision of robotic tasks.

Comprehensive Technical FAQ

Q: Does robotic fabrication architecture actually lower labor costs?

A: Yes. By shifting the labor from “physical execution” to “computational oversight,” we see a reduction in on-site man-hours by up to 70%. However, the cost of a single specialized Robotic Operator is 2.5 times higher than a traditional laborer, meaning the value is found in speed and precision, not just hourly rates.

Q: Can these robots work in rain or snow?

A: Currently, most 6-axis arms require IP65 or IP67 rated “suits” to operate in inclement weather. At Nuvira, our 2026 fleet uses specialized thermal jackets to maintain joint fluid viscosity in temperatures as low as -15 degrees Celsius.

Q: How do you handle structural certification?

A: We use “Digital Twins.” For every physical brick laid by a robot, a digital data point is logged including the exact pressure applied (measured in Newtons) and the timestamp. This creates a 100% transparent “birth certificate” for the building, a process that is currently being reviewed by the AIA’s Technology in Architectural Practice (TAP) Knowledge Community.

Q: What is the lifespan of a robotically fabricated building?

A: Because the material distribution is optimized to the micron, these buildings suffer from 50% less “internal stress” than manual builds. We estimate a 100-year minimum lifespan before major structural intervention is required.

Transform Your Workflow with Nuvira

The transition to robotic fabrication architecture is not a choice; it is a necessity for firms that wish to remain solvent in a high-cost, high-speed future.

Are you ready to stop drawing and start fabricating? Contact our Computational Design team today to integrate robotic workflows into your next project.