Table of Contents

As the global climate shift intensifies, the year 2026 has become a definitive pivot point for the AEC (Architecture, Engineering, and Construction) industry. We are witnessing a transition where the building envelope must evolve from a passive barrier into a high-performance, carbon-sequestering skin. To achieve this, lead architects and developers are increasingly reliant on hempcrete insulation data to justify the replacement of legacy synthetic materials with regenerative infrastructure. The data confirms that bio-composite assemblies are no longer a “fringe” alternative but a primary technical solution for a warming world, capable of mitigating the extreme thermal fluctuations that now define our seasonal reality.

At Nuvira Space: The Institutional Authority on Regenerative Systems

At Nuvira Space, we view the building envelope not as a static barrier, but as a living, respiratory organ. Our mission is to dismantle the reliance on high-carbon assemblies by providing the technical blueprint for materials that do more than just insulate—they regenerate. We recognize that in a world of 50-degree Celsius summers and volatile humidity, the industry standard is no longer sufficient. We advocate for a fundamental shift toward bio-composite systems where carbon-negative performance is the baseline, not the exception. We provide the empirical evidence required to transition from speculative design to realized, high-density performance.

Technical Deep Dive: Hempcrete Insulation Data 2026

Hempcrete is a biocomposite consisting of the woody core of the industrial hemp plant (the shiv) and a hydraulic lime-based binder. Unlike mineral wool or expanded polystyrene (EPS), which rely on trapped air within a synthetic matrix, hempcrete provides a monolithic insulation layer that integrates thermal resistance with massive hygroscopic buffering capacity. By 2026, the refinement of binder chemistry has allowed us to achieve unprecedented consistency in performance metrics.

Core Thermal Metrics and Conductivity

To understand why hempcrete is superior in 2026, you must analyze the relationship between its conductivity and its specific heat capacity. This is not a material that functions through high R-values alone; it functions through thermal phase-shifting.

- Thermal Conductivity ($\lambda$): 0.06 to 0.07 W/mK. This metric defines the rate at which heat energy passes through the material. While higher than some synthetic foams, hempcrete compensates through the “thermal fly-wheel” effect, where the material’s mass prevents rapid temperature swings.

- Typical U-Value: A 350mm thick wall achieves a U-value of 0.17 W/m2K. For context, 2026 high-performance standards in the EU and North America often target 0.15 to 0.18 W/m2K, placing hempcrete in the elite tier of passive thermal envelopes.

- Specific Heat Capacity (c): 1,500 to 1,700 J/kgK. This is the “So What?” for the occupant: the material stores heat energy during solar peak hours and releases it during the nocturnal dip, effectively flattening the building’s energy demand curve and reducing peak cooling loads by up to 40%.

- Density: 275 to 330 kg/m3 for insulation-grade mixes. This density provides the structural rigidity required for non-load-bearing infill while maintaining a lightweight profile that reduces the required dimensions of the primary structural frame, saving on total material costs.

The Carbon Sequestration Equation

The data for 2026 confirms that hempcrete is a primary lever for regenerative infrastructure. In a world of tightening carbon taxes, these numbers represent financial security.

- Biogenic Carbon Sequestration: 307.26 kg CO2/m3 during the growth phase of the hemp. Hemp is a carbon vacuum, pulling CO2 from the atmosphere at a rate that traditional forestry cannot match.

- Net Lifecycle Carbon (A1-A3): After accounting for the carbon-intensive production of lime and transportation, the net lifecycle impact remains approximately -35.5 kg of CO2 per m2 of wall area.

- Harvest Cycle: Hemp reaches maturity in 100 to 120 days, sequestering carbon up to 4 times faster than softwoods, which require 20 to 25 years for comparable biomass production. This rapid cycle allows for a continuous supply of carbon-negative feedstock.

In a market increasingly dominated by 3D-printed neighborhoods, the integration of hemp-lime extrusions represents the next frontier in automated, carbon-negative construction.

Comparative Analysis: Hempcrete vs. Industry Standards

When evaluating hempcrete insulation data, the value becomes apparent in the “Total Performance” category rather than just R-value per inch. Architects must look beyond the static insulation value to understand the dynamic behavior of the assembly over a 50-year lifespan.

| Feature | Hempcrete (350mm) | Mineral Wool + Vapor Barrier | EPS (Polystyrene) |

|---|---|---|---|

| Carbon Profile | Carbon-Negative (-35.5 kg CO2/m2) | Carbon-Intensive (+15 kg CO2/m2) | High Carbon (+30 kg CO2/m2) |

| Moisture Strategy | Vapor-Open (Hygroscopic) | Vapor-Closed (Risk of interstitial rot) | Vapor-Closed (Zero breathability) |

| Thermal Mass | High (1,600 J/kgK) | Negligible | Very Low |

| Fire Class | B-s1, d0 (Fireproof lime skin) | A1 (Non-combustible) | E (Highly Flammable) |

| Acoustic Absorption | 0.80 at 500Hz | 0.60 – 0.70 | 0.20 |

The American Institute of Architects (AIA) has increasingly highlighted these metrics through their COTE® Top Ten program. In fact, referencing the AIA Framework for Design Excellence, hempcrete aligns perfectly with the “Design for Resources” and “Design for Wellness” categories. By eliminating the need for complex, multi-layered vapor barriers, you reduce the risk of building failure and ensure long-term structural integrity. This level of material health is a cornerstone of biophilic interior design, where the tactile and hygroscopic qualities of the wall contribute to a healthier indoor microbiome, free from the off-gassing associated with petrochemical binders.

Concept Project Spotlight: Speculative Internal Concept Study “Aura-12” by Nuvira Space

Project Overview: Rotterdam, Netherlands / Mixed-Use Vertical Forest Our Rotterdam concept, Aura-12, utilizes a timber-frame skeleton with a 400mm hempcrete cast-in-situ envelope. Rotterdam was selected for this study due to its maritime humidity, high water table, and the city’s aggressive 2030 carbon-neutral mandate.

Design Levers Applied

- Dynamic Buffering: Aura-12 uses the 2.78 g/(m²·%RH) hygric buffering value of hempcrete to maintain indoor relative humidity between 40% and 60% without mechanical humidifiers. This reduces the mechanical load by 35% annually, providing a significant reduction in operational expenses.

- Thermal Battery Walls: We specified a 500 x 200 x 300 mm block format for the south-facing facade to maximize the 6.42 R-value (calculated over the full 400mm assembly), ensuring the building remains cool during peak solar gain without HVAC reliance.

- Acoustic Attenuation: The open-pore structure of the hemp shiv absorbs 0.80 NRC, critical for the urban density and noise pollution inherent to Rotterdam’s port-side developments.

- Hybrid Integration: To address foundation loads in Rotterdam’s soft soil, we combined the hempcrete envelope with carbon-negative concrete in the substructure, creating a fully sequestering vertical mass that satisfies the most stringent engineering requirements.

Transferable Takeaway: The synergy between timber and hempcrete creates a “dry-build” speed with “wet-build” thermal mass benefits. Architects can spec thinner timber sections because the hempcrete provides lateral bracing and fire protection, reducing the total volume of timber required by 12% without compromising safety.

The Science of “Lived Experience”: Beyond the Numbers

While the hempcrete insulation data provides the technical justification, the “So What?” lies in the sensory experience of the space. In a standard 2026 apartment insulated with synthetic foam, the air is often stale, requiring high-velocity air changes that create drafts and noise.

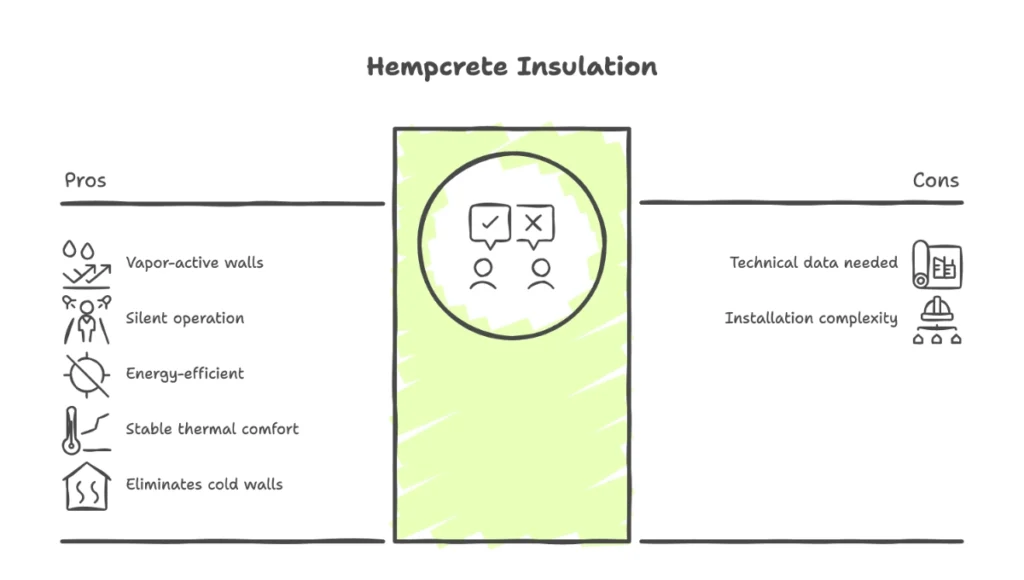

In a Nuvira-specified hempcrete space, the walls are “vapor-active.” When you cook or shower, the walls absorb the excess moisture molecules. When the air dries out, they release them. This process is passive, silent, and requires 0 energy. For the occupant, this translates to a “thermal comfort” sensation that is far more stable than the cycling on-and-off of an air conditioner. The 1,600 J/kgK heat capacity means the interior surface of the wall stays within 2 degrees of the ambient air temperature, eliminating the “cold wall” effect common in glass-and-steel skyscrapers. You aren’t just living in a box; you are living in an environment that actively moderates your well-being.

2030 Future Projection: The Mainstream Pivot

By 2030, we project that regenerative infrastructure will be the regulatory requirement in the EU and North America. The hempcrete insulation data we use today for niche projects will become the standard for municipal housing.

- Carbon Credits: Building owners will trade the 307.26 kg of sequestered CO2 per cubic meter on the open market, essentially turning the building into a financial asset that pays for its own construction over 15 years.

- The End of the Vapor Barrier: As building science catches up to the data, the dangerous reliance on plastic “wraps”—which often trap moisture and cause structural rot—will be phased out in favor of breathable, monolithic biocomposites.

- Automated Fabrication: We are already seeing prototypes of site-ready hempcrete panels being manufactured with 0% VOCs and 0% formaldehyde, allowing for rapid assembly in urban infill projects. This will decentralize construction, allowing local hemp farms to supply regional “micro-factories.”

Comprehensive Technical FAQ

Q: How does hempcrete handle the extreme maritime humidity of cities like Singapore or Rotterdam?

A: Because hempcrete is vapor-permeable and lime is naturally antiseptic, it handles high humidity better than any other material. It prevents “sick building syndrome” by ensuring no condensation occurs within the wall assembly.

- Vapor Permeability: 0.7 to 0.8 mg/m·h·Pa.

- Mold Resistance: pH of 12 (highly alkaline), which is naturally inhospitable to fungal growth.

Q: Can we use hempcrete for load-bearing structures in high-rise applications?

A: No. Hempcrete must be used as an infill.

- Compressive Strength: 0.2 to 0.5 MPa.

- Standard Practice: Use in conjunction with a Primary Structural Frame (PSF) of timber, steel, or carbon-negative concrete.

Q: What is the fire rating for a standard 300mm hempcrete wall?

A: Hempcrete is classified as non-flammable. Each piece of hemp is coated in lime, which prevents combustion.

- Rating: Typically achieves a 120-minute fire rating (REI 120).

- Smoke: Zero toxic off-gassing during fire exposure, unlike EPS which releases toxic gases when burned.

Q: What is the drying time for cast-in-situ applications in 2026?

A: Depending on ambient conditions, a 300mm wall requires 6 to 10 weeks to fully cure. However, with the 2026 Nuvira “Quick-Dry” lime binders, we have reduced this significantly, or it can be bypassed entirely using pre-cast blocks.

Secure Your Regenerative Future

The transition to carbon-negative architecture is not a trend; it is a survival strategy. Utilizing hempcrete insulation data is the first step in de-risking your portfolio against rising energy costs, carbon taxes, and the structural failures of legacy materials.

The AIA’s 2030 Challenge sets a high bar, but with hempcrete, those targets are not just reachable—they are baseline. At Nuvira Space, we provide the specifications, the data, and the vision to transform your next project into a carbon-sink. Do not wait for legislation to force your hand—lead the industry in the shift to regenerative infrastructure today. Reach out to our technical team to integrate these metrics into your next BIM model.