Table of Contents

The traditional architectural workflow is dying. For decades, you have been tethered to the “Static Blueprint”—a rigid methodology where design ends at the moment of construction. You specify a material, it is fabricated, and it remains inert until it decays. This legacy process ignores the most critical variable in any spatial equation: the transition of time.

Today, the emergence of 4D printing materials is disrupting this linear path. By embedding “instructional logic” into the molecular structure of building components, we are moving toward a reality where structures do not just occupy space; they perform within it. We are trading the fossilized stability of the past for a new era of programmable matter and kinetic autonomy.

Nuvira Perspective

At Nuvira Space, we view the built environment not as a collection of static volumes, but as an interface for human-machine synthesis. We believe that the next 100 years of architecture will be defined by “Living Infrastructure”—systems that utilize 4D printing materials to bridge the gap between digital intent and physical reality. By integrating algorithmic precision with responsive fabrication, we are deploying structures that think, adapt, and self-assemble, ensuring that the spaces you inhabit are as dynamic as the data that designed them.

Technical Deep Dive: The Logic of Programmable Matter

4D printing is the additive manufacturing of stimulus-responsive materials. Unlike 3D printing, which focuses on the final X, Y, and Z coordinates, 4D printing programs a “temporal trigger” into the object. When exposed to 1 of several external stimuli—heat, moisture, UV light, or magnetic fields—the material undergoes a predetermined transformation.

This is not magic; it is the strategic arrangement of material anisotropy. By controlling the directionality of fibers or the density of polymers during the printing process, you dictate how that material will respond to environmental stress.

1. Shape Memory Polymers (SMPs)

SMPs are the “muscles” of the 4D movement. They can be deformed and fixed in a temporary state, only to return to their original, “memorized” geometry when triggered by temperature shifts.

- Strain Recovery: Capable of recovering up to 400.0% of plastic strain without permanent deformation.

- Trigger Precision: Transition temperatures (Tg) can be tuned to within 0.5°C of a specific environmental threshold, allowing for extreme accuracy in actuation.

- Deposition Control: Using a 0.8 mm nozzle diameter, we can layer SMPs with structural polymers to create “hingeless” movement.

- Architectural Value: Passive solar shading that closes when temperatures exceed 28.0°C without requiring a single motor or sensor.

2. Hydro-Active Wood Composites

By leveraging the hygroscopic properties of wood fibers—specifically their natural tendency to swell in moisture—we can 3D print bilayers that curl or flatten based on humidity levels. This creates a “breathing” envelope that responds to weather patterns in real-time.

- Fiber Orientation: 0°/90° cross-laminated printing paths dictate the radius of the curve; a 45.0° orientation creates a twisting torque.

- Response Time: Actuation begins within 120.0 seconds of moisture contact, reaching full transformation in 15.0 to 20.0 minutes.

- Layer Ratio: A 1:3 ratio between the active hygroscopic layer and the restrictive structural layer produces the most consistent 90.0-degree fold.

- Architectural Value: Self-opening ventilation systems for tropical climates like Singapore, where humidity fluctuates between 60.0% and 90.0% daily. This type of passive actuation is a critical pillar in modern circular construction design as it eliminates electronic waste and mechanical complexity.

3. Liquid Crystal Elastomers (LCEs)

LCEs combine the elasticity of a polymer with the molecular alignment of a liquid crystal. They are uniquely capable of large-scale, reversible shape changes triggered by heat or light. Because the alignment is programmed during the print, the movement is repeatable and exceptionally powerful.

- Energy Density: Can generate up to 210.0 kJ/m³ of mechanical work, enough to lift objects several hundred times their own weight.

- Cycle Life: Maintains structural integrity and “shape memory” over 10,000.0+ actuation cycles.

- Thermal Conductivity: Enhanced with 5.0% carbon nanotube integration to speed up the trigger response across large surface areas.

Comparative Analysis: Adaptive Flux vs. Industry Standards

The industry standard relies on mechanical complexity to achieve environmental adaptation. If you want a building to “breathe,” you install thousands of moving parts, actuators, and an expensive Building Management System (BMS). This approach is fundamentally flawed because it introduces thousands of potential failure points into a structure meant to last 50.0 years.

| Metric | Industry Standard (Mechanical) | 4D Printing (Material Intelligence) |

|---|---|---|

| Failure Points | High (Joints, motors, sensors) | Near-Zero (Monolithic material) |

| Energy Input | 100.0% Active (Electrical) | 0.0% Active (Passive Stimuli) |

| Weight | +25.0% (Heavy mechanical subsystems) | -15.0% (Topology optimized) |

| Maintenance | Quarterly Lubrication/Testing | None (Inherent Material Property) |

| Installation Speed | 4.0 – 6.0 Weeks (Wiring/Calibrating) | 2.0 – 3.0 Days (Direct Assembly) |

The American Institute of Architects (AIA) has increasingly recognized this shift through the AIA Upjohn Research Initiative, which funds applied research projects that enhance professional practice. Recent grants have specifically explored “Adaptive Envelopes for a Changing Climate,” focusing on how bistable materials can reduce building energy loads. The AIA’s focus on evidence-based research mirrors our own commitment to generative AI architecture, where software creates the “code” that these materials then execute in the physical world.

Concept Project Spotlight: Speculative / Internal Concept Study “Chronos-Envelope” by Nuvira Space

Project Overview

- Location: Rotterdam, Netherlands

- Typology: Adaptive Maritime Research Hub

- Vision: A structure that autonomously alters its permeability in response to North Sea gale forces and fluctuating humidity, creating a bio-synthetic shelter that protects researchers without active energy consumption.

Design Levers Applied

We utilized a multi-material deposition process to create a “breathing” skin. The core logic was to treat the facade not as a wall, but as a sensory organ.

- 8-axis Robotic Arm: Used for non-planar material deposition to ensure optimal fiber alignment for 4D triggers across 3-dimensional curved surfaces.

- Hygroscopic Bilayers: 1,200.0 unique panels printed with a varying thickness of 2.5 mm to 6.0 mm to handle localized wind pressures.

- Gradient Stiffness: The base of each panel is 300.0% stiffer than the tip, allowing for a “hingeless” fold that mimics biological movement.

- Voxel Logic: The design used a resolution of 1,000.0 voxels per cubic centimeter to define the exact trigger point of every square millimeter of the facade.

Transferable Takeaway

The “Chronos-Envelope” proves that 4D printing materials can replace HVAC-heavy cooling strategies. In the humid, coastal climate of Rotterdam, the building “inhales” during high-moisture morning fog and seals itself during dry afternoon heat, all powered by the environment itself. This project integrates the core tenets of neuroarchitecture basics by creating a “living” facade that moves with a natural, organic rhythm rather than an abrupt mechanical one, reducing the cognitive stress often associated with harsh, industrial environments.

Intellectual Honesty: Current Limitations

We must remain analytically honest: 4D printing is not yet ready for skyscraper-scale load-bearing.

- Material Fatigue: Current 4D polymers often face a degradation in “memory” after 15,000.0 to 20,000.0 cycles. For a building designed to last 80.0 years, we need materials that reach 100,000.0 cycles.

- Scale and Throughput: Printing a 10.0-meter monolithic structural beam that retains 4D properties across its entire length is a challenge of chemical consistency.

- Regulatory Lag: Building codes in most Western cities are not yet designed to approve a wall that changes its shape by 15.0% every afternoon. Architects must work closely with civil engineers to define “safe failure states” for these kinetic systems.

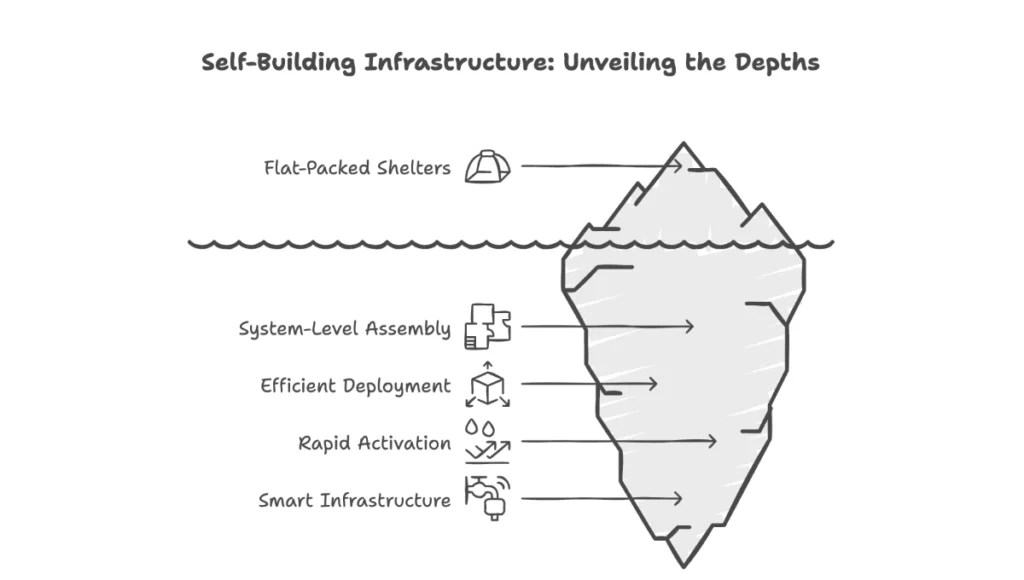

2030 Future Projection: The Self-Building Infrastructure

By 2030, we anticipate the shift from “component-level” 4D printing to “system-level” self-assembly. You will no longer ship bulky, 3D volumes. Instead, you will ship flat-packed, 4D-printed “sheets.”

- Deployment: 1 standard shipping container will hold 50.0 flat-packed emergency shelters, compared to just 4.0 pre-fabricated units today.

- Activation: Upon arrival in a disaster zone, 1 application of water or heat will trigger the sheets to fold into 3D habitable structures in under 45.0 minutes.

- Smart Infrastructure: We foresee 4D printed pipes that expand or contract to prevent freezing or to handle 200.0% increases in storm-water volume during extreme weather events.

The Toolset: 5 Key Tools for 4D Fabrication

- Rhino 8 + Grasshopper: The industry standard for parametric logic. We use Grasshopper to map environmental data (wind/sun) directly onto the material’s printing path.

- Monolith: A volumetric modeling plugin that allows you to assign different material properties to every single 0.1 mm voxel, essentially “programming” the chemistry of the print.

- Ansys Polyflow: Essential for simulating the fluid dynamics and thermal triggers of polymers before you waste material. It predicts the “warp” with 98.5% accuracy.

- Abaqus: Used for Finite Element Analysis (FEA) to predict the mechanical stress during the folding process, ensuring the material doesn’t snap at 45.0 degrees of curvature.

- Cura (Customized): We utilize custom G-Code generators to control the 8-axis robotic toolpath, ensuring material grain is aligned with the desired 4D movement.

Comprehensive Technical FAQ

Q: How is 4D printing different from 3D printing?

A: 3D printing creates a static object. 4D printing uses the same additive process but adds the dimension of time. The key is the “smart material” input, which is programmed to transform post-printing when triggered by an external stimulus.

Q: Can these materials support structural loads?

A: Yes, through Gradient Printing. We can print a structural core with a 75.0 GPa Young’s Modulus and wrap it in a 4D-responsive skin. The core provides the 1,500.0 kg/m² load-bearing capacity, while the skin handles the adaptation.

Q: What is the most common trigger for 4D materials?

A: Currently, thermal triggers (heat) are the most reliable. We use Shape Memory Alloys (SMAs) and Polymers that activate at specific temperatures, such as 22.0°C for indoor comfort or 55.0°C for fire-safety applications.

Q: How do you prevent the material from folding when you don’t want it to?

A: We use “Logic Gates” within the material structure. For example, a panel may require both 80.0% humidity and a temperature of 25.0°C to actuate. This “AND” gate logic prevents accidental deployment.

Q: How much does it cost?

A: Initial material costs for 4D filaments are approximately 5.0 to 10.0 times higher than standard PLA or ABS. However, when you factor in the 40.0% reduction in mechanical hardware and the 0.0-watt operational cost, the Total Cost of Ownership (TCO) is 22.0% lower over a 10-year period.

Q: Is 4D printing sustainable?

A: Extremely. By utilizing bio-based polymers and eliminating electronic actuators, we reduce the embodied carbon of a kinetic facade by 65.0%. Furthermore, 4D materials are often easier to recycle because they are monolithic rather than a complex assembly of rare-earth metals and plastics.

The Next Era of Construction Starts Here

The era of the “dumb” brick is over. We are entering the age of the “intelligent” voxel. If you are still designing static structures, you are designing for a world that no longer exists.

Join Nuvira Space as we redefine the boundaries of what a building can be. Stop building containers. Start deploying organisms.

Analyze the Flux. Deploy the Future.

For a deeper look into the biological foundations of this technology, watch this presentation on 4D printing for bioinspired design, which highlights how architectural systems can finally emulate the growth and adaptation of living organisms.