Table of Contents

The Atmosphere as a Resource: Redefining the Building Envelope

Algae Bio-Curtains represent a fundamental shift in how we approach the building envelope as the global climate transition moves from a theoretical risk to a localized operational reality. As urban heat islands intensify and atmospheric CO2 levels hover near 420 ppm, the traditional “sealed box” philosophy of glass architecture has reached its metabolic limit.

Static glazing is no longer a neutral asset; it is a thermal liability. To thrive in a climate-volatile future, the building skin must evolve from a passive barrier into an active, respiratory organ through the integration of photobioreactive technologies.

Nuvira Perspective: Architecture as a Living Organism

At Nuvira Space, we view the transition to regenerative infrastructure as an evolution of the building’s biological intelligence. We reject the notion that sustainability is a checklist of efficiency metrics; instead, we treat the building envelope as a site of carbon sequestration and energy synthesis. By integrating Algae Bio-Curtains into the glass facade, you are not merely “offsetting” impact—you are installing a bioreactor that transforms the liability of solar radiation into the asset of biomass. Our institutional stance is clear: the future of high-performance architecture is not found in inert materials, but in the kinetic, photosynthetic potential of microalgae.

Technical Deep Dive: 6 Systems Redefining the Modern Facade

Microalgae are 10 to 50 times more efficient at capturing carbon than terrestrial plants. When integrated into bio-curtains, they utilize the 1,000 to 1,500 watts per square meter of solar energy hitting a glass facade to drive biomass production. This process, known as photobioreaction, occurs within specialized cavities where nutrient-rich water circulates, creating a high-density cellular suspension that filters sunlight while scrubbing the atmosphere.

1. The Photo.Synth.Etica System (ecoLogicStudio)

This system utilizes large-scale, 32-meter long bioplastic ETFE modules. The “curtain” acts as a digital-biological hybrid, where algae-enriched water flows through serpentine micro-channels. ETFE (Ethylene Tetrafluoroethylene) is chosen for its 95% light transmission and its weight—which is approximately 1% of the weight of glass—allowing for massive installations that do not compromise the structural integrity of the primary frame.

- Sequestration Rate: 1 kilogram of CO2 absorbed per day, equivalent to the capacity of 20 large mature trees. Over a 365-day cycle, a single module can neutralize the carbon output of a standard passenger vehicle driving 4,000 kilometers.

- Spatial Function: The system provides 30% to 60% dynamic shading, reducing the cooling load on the HVAC system by up to 25%. This reduction is critical in tropical climates where cooling accounts for 60% of total building energy use.

- Fluid Dynamics: The system operates with a culture density of 2 to 5 grams of dry biomass per liter, requiring a pump pressure of 1.5 bars to maintain constant circulation.

- The “So What?”: For a building occupant, this means a significant reduction in solar glare and a visible, kinetic connection to the building’s air-purification process. You are inhabiting a space that actively defends its own internal climate.

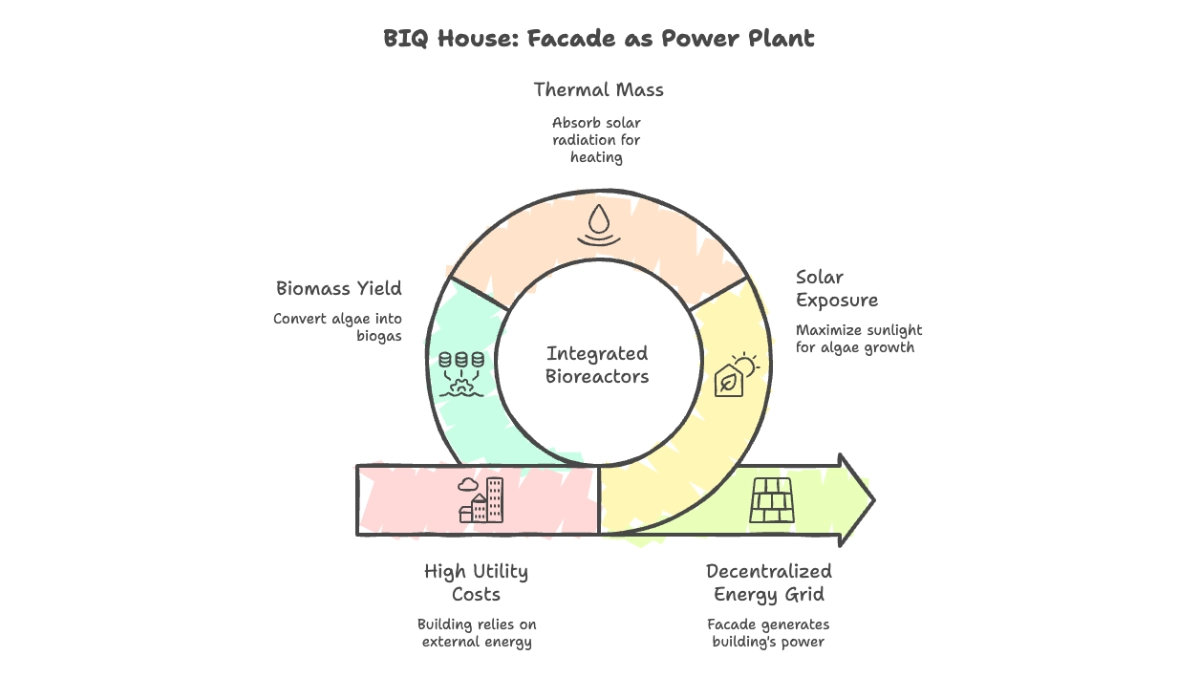

2. The BIQ House Bioreactors (Hamburg)

The world’s first full-scale implementation in Hamburg, Germany, utilizes 200 square meters of integrated photo-bioreactors (PBRs). These panels are mounted on the southwest and southeast elevations to maximize solar exposure.

- Thermal Mass: The 2-centimeter thick water-filled panels provide a thermal buffer that absorbs 38% of solar radiation. This thermal energy is harvested via a heat exchanger, maintaining a water temperature of 40 degrees Celsius for domestic use.

- Biomass Yield: Produces 30 grams of dry biomass per square meter daily, which is harvested and converted into biogas via an off-site anaerobic digester. This yield represents an energy density of approximately 5.5 kilowatt-hours per kilogram of dry algae.

- Efficiency Metrics: The 48.5% efficiency of converting light into biomass means lower long-term utility costs for residents, as the building effectively subsidizes its own heating demand.

- The “So What?”: This turns a residential building into a power plant. By living here, you participate in a decentralized energy grid where your facade is the primary generator.

3. Urban Algae Folly (Milan)

A modular system designed for public engagement, using high-transparency glass tubes to cultivate Spirulina. This system is designed as an architectural pavilion but is scalable to large-scale urban facades.

- Oxygen Output: Releases 100 liters of pure oxygen for every 1 kilogram of CO2 consumed. This localized oxygenation can improve the cognitive performance of occupants by reducing indoor CO2 “brain fog” levels from 1,200 ppm to a crisp 600 ppm.

- Luminescence: At night, the system utilizes integrated LED sensors that react to air quality, glowing brighter as pollution levels rise. These 12-volt sensors sample the air every 60 seconds, providing real-time environmental feedback.

- Growth Speed: Under optimal 2,000-lux conditions, the algae population doubles every 24 hours, requiring a robust harvesting schedule to prevent “culture crash.”

- The “So What?”: This transforms the sensory experience of the streetscape, making air quality a visible, navigable metric for the public. It serves as a biological beacon of urban health.

4. Solar Leaf Integrated Panels

These are flat-panel PBRs specifically designed for high-rise glass curtain walls, offering a standardized approach to regenerative infrastructure.

- Dimensions: Standardized 2.5-meter by 0.7-meter panels that clip onto existing mullion systems. Each panel contains 15 liters of culture medium.

- Fluid Dynamics: Operates at a flow rate of 5 liters per minute to prevent algae sedimentation and ensure uniform CO2 distribution. The use of “gas-lift” technology ensures that 98% of the CO2 injected into the base of the panel is absorbed by the cells before reaching the surface.

- Scalability: For a 50-story tower, these panels can cover 4,500 square meters of surface area, sequestering 120 tons of carbon annually.

- The “So What?”: Because the panels are modular, you can perform maintenance on a single 1.75-square-meter section without compromising the entire facade’s performance. This ensures 99% uptime for the building’s carbon-scrubbing capabilities.

5. Green Loop Bio-shading

This system focuses on the interplay between light and growth, utilizing the algae as a programmable filter for the building interior.

- Photosynthetic Control: Uses 550-nanometer light sensors to optimize the pump speed based on real-time solar intensity. When light levels exceed 80,000 lux, the system increases nutrient delivery to accelerate growth and thicken the “biological screen.”

- Carbon-Negative Impact: Neutralizes the embodied carbon of the glass facade (typically 25 kilograms of CO2 per square meter for triple glazing) within 7 to 12 years of operation.

- Heat Recovery: Recovers 150 megajoules of thermal energy per square meter annually, which is redirected to the building’s pre-heat coil for the ventilation system.

- The “So What?”: You are effectively erasing the environmental “debt” of your building’s construction while you sleep. The facade acts as an automated environmental manager.

6. Bio-Polymer Textile Curtains

A lighter, more flexible alternative to glass-housed systems, using 0.5-millimeter thick specialized polymers that can be draped or tensioned.

- Weight: Weighs only 2.1 kilograms per square meter when fully saturated with culture medium, compared to 45 kilograms per square meter for standard PBR glass.

- Durability: UV-stabilized for a 15-year lifecycle, with the polymer maintaining 92% of its tensile strength (rated at 2500 N/5cm) even under extreme solar exposure.

- Adaptive Geometry: The curtains can be adjusted via 24-volt actuators to change their angle by 45 degrees, tracking the sun’s path for a 15% increase in photosynthetic efficiency.

- The “So What?”: This allows for the retrofitting of older 1980s-era glass buildings that cannot support the structural weight of heavy glass-and-steel bioreactors. It is the most accessible entry point for heritage buildings transitioning to a carbon-negative future.

Comparative Analysis: Algae vs. Industry Standard Glazing

To understand why you should pivot to regenerative infrastructure, look at the delta between current high-performance glass and bio-active systems.

| Metric | Triple-Pane Low-E Glass (Standard) | Algae Bio-Curtain (Regenerative) |

|---|---|---|

| Carbon Profile | Carbon-intensive production (High Embodied) | Carbon-Negative (Active Sequestration) |

| Solar Gain (SHGC) | Fixed at 0.20 to 0.35 | Dynamic: 0.10 to 0.80 (Grows with sun) |

| Energy Generation | 0 kWh/sqm (Energy Consumer) | 15–30 kWh/sqm/year (Biomass/Heat) |

| Air Quality | Neutral (Recirculates filtered air) | Positive (Active CO2 scrubbing) |

| Maintenance | Low (Cleaning only) | Moderate (Fluid and nutrient management) |

| Lifespan Impact | Constant degradation of coatings | Biological renewal through culture cycles |

While standard glazing attempts to block the environment out, the bio-curtain invites the environment in to be processed. In a city like Singapore, where humidity and solar heat gain are constant, the 85% solar absorption rate of an algae system can reduce a building’s total cooling demand by 12,000 kWh annually for a medium-sized office floor. Furthermore, the 20 grams of nitrogen removed from the atmosphere per square meter of facade helps mitigate the urban smog that characterizes high-density metropolitan areas.

2030 Future Projection: The Bio-Digital Facade

By 2030, the “smart building” will be replaced by the “living building.” We anticipate that building codes in Tier 1 cities like Copenhagen and Rotterdam will mandate a minimum carbon-sequestration coefficient for all new glass facades. You will no longer see skyscrapers as reflective mirrors, but as translucent green prisms that actively repair their local microclimate.

Artificial Intelligence will manage these facades, adjusting nutrient flow based on 48-hour weather forecasts and local air pollution spikes detected by the city’s sensor grid. The biomass harvested from your office window will likely fuel the building’s backup generators or be processed into bio-plastic furniture for the lobby, completing a 100% circular material loop within the urban footprint. Buildings will no longer be static assets; they will be participants in a global biological economy, trading carbon credits in real-time based on their facade’s hourly sequestration rates.

Comprehensive Technical FAQ

Q: How does the system handle winter temperatures?

A: Most systems, like those in the BIQ House, utilize a closed-loop water circuit. In cold climates, the 100% solar absorption keeps the culture medium between 15 and 25 degrees Celsius. If the temperature drops further, the system integrates with the building’s waste heat recovery, using “exhaust heat” to maintain the algae’s metabolic rate. This ensures that even in sub-zero external conditions, the internal bioreactor remains productive. For deeper insights into designing regenerative envelopes for extreme winter conditions, see our analysis of Yosemite’s 2026 Winter Storms: 5 Revolutionary Design Lessons.

Q: Is the maintenance burden realistic for a commercial property?

A: Yes. Modern systems are automated through a Building Management System (BMS). You only need to manage the nutrient injection and biomass harvesting, which occurs every 2 to 4 weeks. The 5-micron filtration systems ensure the glass remains clear of “bio-fouling” (algae sticking to the sides), maintaining aesthetic clarity. The typical labor requirement is approximately 10 hours per month for a 500-square-meter facade.

Q: Does the green tint affect the color rendering index (CRI) inside?

A: The algae density is dynamic. When the sun is at its zenith, the algae thicken to provide a 70% tint (Green CRI), which actually reduces eye strain by filtering harsh blue light. On overcast days, the system pumps the algae into bottom storage tanks, returning the glass to 95% transparency. The shift is gradual, occurring over a 20-minute cycle to allow the human eye to adapt without noticing the transition.

Q: What is the risk of a “culture crash” or contamination?

A: Each panel is isolated through a series of one-way valves. If a contamination event occurs in one module, it cannot spread to the rest of the 2,000-square-meter facade. Integrated UV-C sterilizers in the circulation loop kill 99.9% of invasive bacteria and fungi, ensuring the monoculture of Chlorella or Spirulina remains stable and productive.

Q: How is the biomass actually used on-site?

A: In a 10,000-square-meter installation, you will produce roughly 1,000 kilograms of biomass monthly. This can be processed into 400 cubic meters of biogas, providing enough energy to power the building’s common area lighting for 5 days. Alternatively, it can be dried and sold as a high-protein feedstock, generating an ancillary revenue stream of approximately $2,000 per month.

Transition to Regenerative Infrastructure

The era of passive sustainability is over. You can continue to specify materials that merely “do less harm,” or you can choose to deploy architecture that heals the atmosphere. Algae bio-curtains are the most potent tool in the designer’s arsenal for achieving a carbon-negative reality without sacrificing the transparency of modern glass facades. The shift to biological architecture is not a luxury; it is a fundamental requirement for the resilience of our urban future.